Tired of chipped tiles and uneven cuts? Choosing the wrong blade can ruin your project and cost you time and money. Let’s find the perfect solution.

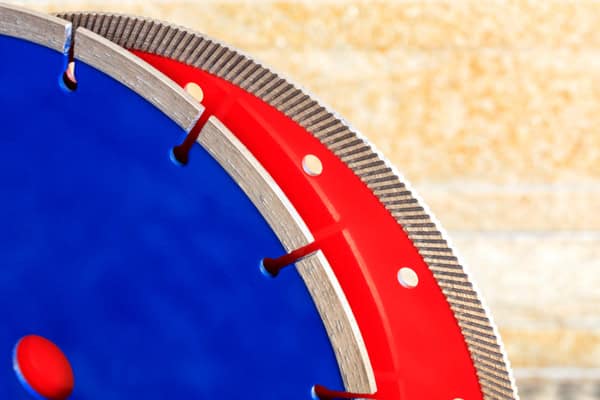

The best angle grinder blade for tile cutting is a continuous rim diamond blade. This blade provides clean cuts on ceramic, porcelain and natural stone tiles without chipping.

Finding the right blade1 involves understanding your material and project needs2. Let’s explore the key factors that make one blade better than others.

What is the Best Diamond Blade for 20mm Porcelain?

Porcelain tiles3 are beautiful but challenging to cut. Many professionals struggle with chips and cracks when using the wrong blades4.

For 20mm porcelain tiles, use a turbo rim diamond blade with medium bond hardness. This design combines cutting speed with smooth edges, perfect for thick porcelain applications.

Understanding Porcelain Tile Cutting Needs

Porcelain tiles require special consideration because:

- Material hardness: They rank 8-9 on Mohs scale

- Thickness: 20mm requires more cutting power

- Fragility: Prone to chipping at edges

Here’s a comparison of blade types:

| Tipo de lâmina | Velocidade de corte | Edge Finish | Best For |

|---|---|---|---|

| Aro Contínuo | Slow | Smooth | Thin tiles |

| Aro Turbo | Médio | Good | 20mm porcelain |

| Segmented | Fast | Rough | Demolition |

The turbo rim design works best because it:

- Disperses heat quickly

- Clears debris effectively

- Provides balanced speed and finish

What is the Most Difficult Tile to Cut?

Some tiles make even experienced professionals hesitate. The wrong blade choice leads to wasted materials and frustration.

Large format porcelain tiles (1200x2400mm) with full-body coloring are the most difficult to cut. Their size, thickness (up to 20mm), and hardness require specialized blades and techniques.

Challenges With Difficult Tiles

These tiles present multiple cutting challenges:

- Size and weight: Hard to maneuver during cutting

- Material hardness: Wears down blades quickly

- Edge integrity: Easily chips without proper support

Solutions include:

- Using bridge saws for stability

- Implementing proper support systems

- Applying masking tape along cut lines

Our factory specifically designs blades for these applications with:

- Extra diamond concentration

- Special bond formulas

- Reinforced cores

What Material Can a Diamond Blade Cut?

Diamond blades seem magical, but they have limitations. Understanding these prevents tool damage5 e safety hazards6.

Diamond blades cut hard, abrasive materials including concrete, brick, stone, ceramic, and porcelain. They cannot effectively cut steel, wood, or plastic due to bonding incompatibility.

Material Compatibility Guide

The cutting ability depends on:

- Blade design: Segmented vs. continuous rim

- Diamond quality: Grit size and concentration

- Bond hardness: Soft to hard bonds

Here’s a quick reference:

| Material | Tipo de lâmina | Bond Hardness | Notes |

|---|---|---|---|

| Concreto | Segmented | Hard | Wet cutting preferred |

| Porcelana | Turbo | Médio | Prevent chipping |

| Granito | Continuous | Soft | Polished finish |

| Tijolo | Segmented | Médio | Dry cutting OK |

| Aço | Not recommended | N/A | Use abrasive blades |

Common misconceptions:

- "Diamond blades cut anything" – False

- "All diamond blades are equal" – False

- "Blades never wear out" – False

Angle grinders can be used to cut tiles, bricks, granite, marble, and other materials. When using an angle grinder to cut concrete, segmented rim diamond blades7 are typically the preferred option. Continuous rim angle grinder8 diamond blades, in contrast, are designed for the precise cutting of materials like marble, granite, porcelain tile, and ceramic tile.

What is the Best Diamond Saw Blade for Concrete?

Concrete cutting demands durability and cutting speed. The wrong blade choice leads to rapid wear and uneven cuts.

For concrete cutting, choose a segmented diamond blade with hard metal bond (16-20mm segments). This design clears debris effectively while maintaining cut speed in abrasive materials.

Concrete Cutting Considerations

Concrete presents unique challenges:

- Abrasiveness: Wears down blades quickly

- Rebar presence: Requires special blades

- Cut depth: Impacts blade selection

Key factors in concrete blades:

- Diamond quality: High-grade industrial diamonds last longer

- Segment design: Wider segments for deeper cuts

- Cooling method: Wet vs. dry applications

Our factory produces specialized concrete blades with:

- Extra diamond concentration

- Tough metal bonds

- Laser-welded segments

- Vibration-reducing slots

Segmented rim angle grinder concrete blades feature a toothed rim that serves two crucial functions: the removal of dust and the cooling of the blade through air circulation. Turbo rim angle grinder diamond blades, on the other hand, are specifically designed to deliver faster cutting speeds for both wet and dry operations.

Conclusão

Choosing the right blade depends on your material and project requirements. Quality diamond blades save time and produce better results.

-

Understanding how to select the right blade can significantly improve your project outcomes and efficiency. ↩

-

This resource will provide insights into aligning your blade choice with specific project requirements. ↩

-

Explore this link to discover the best tools and techniques for cutting porcelain tiles cleanly and effectively, avoiding common pitfalls. ↩

-

Learn about the risks and issues associated with using incorrect blades, helping you make informed choices for your projects. ↩

-

Learn how to prevent tool damage when using diamond blades, which is crucial for maintaining your tools and ensuring safety. ↩

-

Discover the safety hazards related to diamond blades to protect yourself and others while working with these tools. ↩

-

Learn about segmented rim diamond blades and their advantages for cutting concrete and other materials. ↩

-

Explore this link to understand the versatility and applications of angle grinders in various projects. ↩