Cobalt Bits

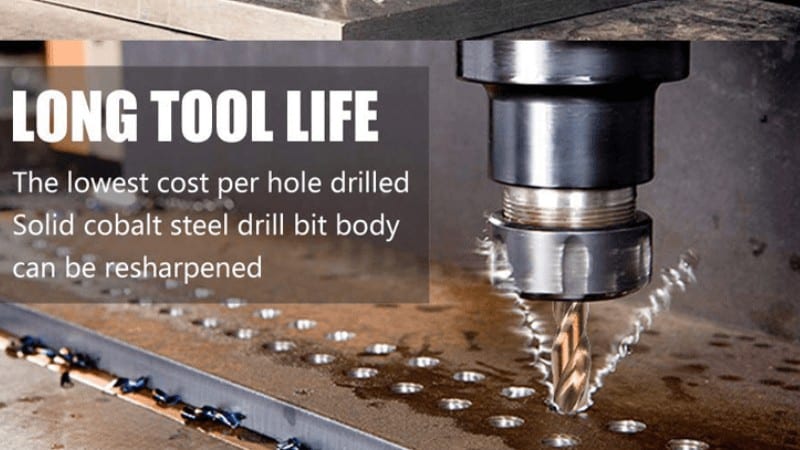

Cobalt drill bits are incredibly strong and can be operated at much higher speeds than a standard HSS drill bit.

The ability to withstand heat means that cobalt bits perform for long periods without cooling or the need for cutting fluid.

Cobalt bits are most often used to cut through hardened and abrasive materials, including bronze, cast iron, stainless steel, and titanium.

Tenyu Cobalt Bits Video

Why Tenyu

Cobalt Bits

Unrelenting Customer Support We never get tired of giving our clients the support and assistance they need! Do you have a question before the sale? Do you yearn to learn more about our lineup of taper length drill bits and can’t decide which one to go with? Contact us and we’ll answer all your questions and concerns!

Expertise and Professionalism Our employees all have a combined experience amounting to 70 years in blacksmithing and in toolmaking. We’re sure that we’ll be able to produce the exact taper length drill bits you need for your business!

Progressiveness and Flexibility Tenyu Tools Co., Ltd. breeds on new products and we you will never have any trouble if you want to innovate or be different compared to other suppliers and manufacturers in the industry. In terms of creativity, you can absolutely count on us!

Swift and Fast Delivery With Tenyu Tools Co., Ltd., you’ll never have a problem when it comes to delivery. We’re known for lightning-speed delivery. Thanks to our partnerships with some of the country’s top courier, as well as freight and cargo services, we can get you the orders in less than two (2) months!

Quality, safety and cost efficiency are our commitments .We are sincere partner to all our clients, irrespective of their sizes. All over the world.

Features and Specs of Our Cobalt Bits

Material | Cobalt Available: M35(Cobalt 5%) M42 (Cobalt 8%) |

Processes | Rolled, Fully Ground |

Sizes Available | 0.2mm to 13mm, 1/16 inches to 1 inch |

Shank Type | Hex Shank, Reduced Shank, Tapered Shank, Tri-Flat Sank, Double R Hex Shank |

Flute Type | Regular Flute, Parabolic Flute, Heavy Duty Web Flute, Thick Web With Parabolic Flute |

Surface Finishing | Black Oxide Coating, Amber Color Coating |

NOTE: These aren’t the only things our cobalt drill bits have. You will be able to find more than these! We’ll be unraveling those when you experience working with us.

What are Cobalt Drill Bits Used For?

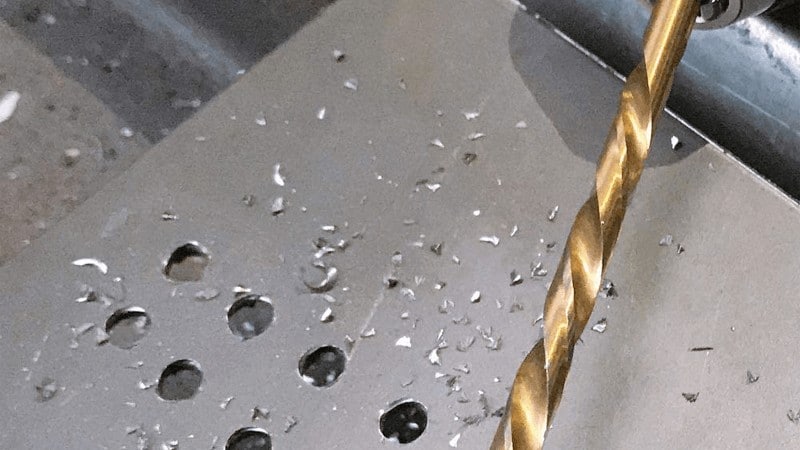

Cobalt bits are one of the most versatile types of drill bits available.

As a result, cobalt bits are an essential tool for any welder or metalworker. In addition to their durability, cobalt bits also have a high resistance to heat.

Cobalt bits are available in a variety of sizes and styles, making them suitable for use in a wide range of drilling applications.

Cotalt Bits for Metal Multi Holes Drilling

Are Cobalt Drill Bits Worth It?

Cobalt bits are made of a cobalt-based steel that contains 5-8% cobalt.

This type of steel is extremely hard and can withstand high temperatures without losing its sharpness.

Cobalt bits are the preferred choice for drilling hard alloy steels, tool steels, stainless steel, and aluminum alloys. They are also less likely to break than standard bits.

When shopping for cobalt bits, be sure to select the correct size and type for your project.

Cobalt Bits for Harden Metal

Is Cobalt the Strongest Drill Bit?

When you need a material that can put holes in hardened steel, cobalt alloy drill bits are the only answer.

The cobalt gives the steel alloy extra strength, making it ideal for drilling through tough materials.

In addition, cobalt drill bits are also resistant to heat and wear, making them last longer than other types of drill bits. As a result, cobalt drill bits are the best choice for any application that requires extreme strength and durability.

Strongest Cobalt Bits for Metal Drilling

What is the Difference Between M35 and M42 Cobalt Drill Bits?

Cobalt bits are particularly effective in cutting through hard metals such as stainless steel. This is due to the higher cobalt content, which makes the bits harder and more resistant to wear.

M35 cobalt bits are ideal for general purpose use, while M42 cobalt bits are better suited for more demanding applications.

The higher cobalt content also makes M42 bits more expensive, but the increased performance is often worth the extra cost.

When choosing between M35 and M42 cobalt bits, it is important to consider the specific needs of the application. In most cases, M35 cobalt bits will provide adequate performance, but for tougher jobs, M42 may be the better choice.

Cobalt Bits with Different Kinds of Surface Finish

What is the Toughest Drill Bit for Metal?

Cobalt bits are made with a cobalt steel alloy that contains 5 to 8 percent cobalt. The cobalt makes the steel harder, so cobalt bits can drill through tougher metals.

They’re also less likely to overheat. Carbide bits have an even higher cobalt content, making them the hardest and strongest type of drill bit.

If you’re looking for cobalt bits that can handle tougher drilling jobs, look for one with a higher cobalt content. And if you’re not sure which type of cobalt bit to choose, ask us for help.

Cobalt Bits for Metal Drilling

Is Cobalt Stronger than Titanium?

The hardness of cobalt bits is one defining factor in their usefulness for certain applications.

As mentioned earlier, cobalt bits are just a bit harder than titanium bits, making them ideal for use in high-speed drilling and other situations where maximum hardness is desired.

In addition to their hardness, cobalt bits also have a high melting point, making them ideal for use in high-temperature applications.

Finally, cobalt bits are resistant to corrosion and wear, making them ideal for use in demanding environments.

When taken together, these properties make cobalt an ideal choice for a wide range of drilling and machining applications.

Cobalt Drill Bits – Your Best Choice

Can I use Cobalt Drill Bits on Concrete?

Cobalt drill bits are specially designed for use with stainless steel and other hard metals.

They are made of a cobalt alloy, which makes them harder and more resistant to wear than carbon steel or high-speed steel bits.

Cobalt bits also have a higher melting point, which means they can withstand higher drilling temperatures.

As a result, cobalt bits are the best choice for drilling through stainless steel and other hard metals. Carbide-tipped drill bits are another option for drilling through hard materials.

Carbide is an extremely hard material that stays sharp longer than cobalt or high-speed steel. As a result, carbide-tipped bits are the best choice for tough drilling applications such as concrete, tile and masonry.

Can I use Cobalt Drill Bits on Wood?

Cobalt bits are made of cobalt steel, which is harder than high-speed steel (HSS).

They can also drill through plastic and wood, although they are more brittle than standard HSS bits and can readily shatter.

Cobalt bits are also more expensive than HSS bits. For these reasons, cobalt bits are best used for specific applications where their hardness and brittleness are an advantage.

Cobalt Bits for Wood

Can you use Cobalt Drill Bits with a Hand Drill?

Cobalt bits are made of cobalt steel, which is harder than high-speed steel (HSS).

This makes them ideal for drilling through tough materials such as hardened and stainless steel.

They can also drill through plastic and wood, although cobalt bits are more brittle than standard HSS bits and can readily shatter.

When choosing a cobalt bit, it’s important to consider the type of material you’ll be drilling through, as well as the size and style of the hole you need to create.

With the right cobalt bit, you can easily drill through even the most difficult materials.

Use Cobalt Bits with Hand Drill

What is the Best Drill Bit to Drill Hardened Steel?

When it comes to drilling through hardened metal or steel, cobalt drill bits are the clear choice.

These bits use a cobalt alloy, which includes 5%–8% cobalt. This cobalt is blended into the steel, so the hardness of the bit doesn’t wear off with a coating (like titanium bits).

As a result, cobalt drill bits are able to withstand more wear and tear, making them ideal for repeated use.

In addition, cobalt bits are less likely to break or shatter under heavy-duty conditions.

For these reasons, cobalt drill bits are the preferred choice for anyone looking to drill through hardened metal or steel.

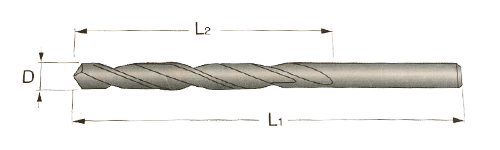

DIN338 Cobalt Bits Dimensions Chart

| DIN338 Cobalt Hss Drill Bits | ||||

| Diameter (D1) | Shank Type | Flute Length | Overall Length | |

| mm | Inch | L2 | L1 | |

| 1.0 | Straight Shank Cobalt Bits | 12 | 34 | |

| 1.1 | Straight Shank Cobalt Bits | 14 | 36 | |

| 1.2 | Straight Shank Cobalt Bits | 16 | 38 | |

| 1.3 | Straight Shank Cobalt Bits | 16 | 38 | |

| 1.4 | Straight Shank Cobalt Bits | 18 | 40 | |

| 1.5 | Straight Shank Cobalt Bits | 20 | 43 | |

| 1.59 | 1/16″ | Straight Shank Cobalt Bits | 20 | 43 |

| 1.6 | Straight Shank Cobalt Bits | 18 | 40 | |

| 1.7 | Straight Shank Cobalt Bits | 20 | 43 | |

| 1.8 | Straight Shank Cobalt Bits | 22 | 46 | |

| 1.9 | Straight Shank Cobalt Bits | 22 | 46 | |

| 1.98 | 5/64″ | Straight Shank Cobalt Bits | 24 | 49 |

| 2.0 | Straight Shank Cobalt Bits | 24 | 49 | |

| 2.1 | Straight Shank Cobalt Bits | 24 | 49 | |

| 2.2 | Straight Shank Cobalt Bits | 27 | 53 | |

| 2.3 | Straight Shank Cobalt Bits | 27 | 53 | |

| 2.38 | 3/32″ | Straight Shank Cobalt Bits | 30 | 57 |

| 2.4 | Straight Shank Cobalt Bits | 30 | 57 | |

| 2.5 | Straight Shank Cobalt Bits | 30 | 57 | |

| 2.6 | Straight Shank Cobalt Bits | 30 | 57 | |

| 2.7 | Straight Shank Cobalt Bits | 33 | 61 | |

| 2.78 | 7/64″ | Straight Shank Cobalt Bits | 33 | 61 |

| 2.8 | Straight Shank Cobalt Bits | 33 | 61 | |

| 2.9 | Straight Shank Cobalt Bits | 33 | 61 | |

| 3.0 | Straight Shank Cobalt Bits | 33 | 61 | |

| 3.1 | Straight Shank Cobalt Bits | 36 | 65 | |

| 3.17 | 1/8″ | Straight Shank Cobalt Bits | 36 | 65 |

| 3.2 | Straight Shank Cobalt Bits | 36 | 65 | |

| 3.3 | Straight Shank Cobalt Bits | 36 | 65 | |

| 3.4 | Straight Shank Cobalt Bits | 39 | 70 | |

| 3.5 | Straight Shank Cobalt Bits | 39 | 70 | |

| 3.57 | 9/64″ | Straight Shank Cobalt Bits | 39 | 70 |

| 3.6 | Straight Shank Cobalt Bits | 39 | 70 | |

| 3.7 | Straight Shank Cobalt Bits | 39 | 70 | |

| 3.8 | Straight Shank Cobalt Bits | 43 | 75 | |

| 3.9 | Straight Shank Cobalt Bits | 43 | 75 | |

| 3.97 | 5/32″ | Straight Shank Cobalt Bits | 43 | 75 |

| 4.0 | Straight Shank Cobalt Bits | 43 | 75 | |

| 4.1 | Straight Shank Cobalt Bits | 43 | 75 | |

| 4.2 | Straight Shank Cobalt Bits | 43 | 75 | |

| 4.3 | Straight Shank Cobalt Bits | 47 | 80 | |

| 4.37 | 11/64″ | Straight Shank Cobalt Bits | 47 | 80 |

| 4.4 | Straight Shank Cobalt Bits | 47 | 80 | |

| 4.5 | Straight Shank Cobalt Bits | 47 | 80 | |

| 4.6 | Straight Shank Cobalt Bits | 47 | 80 | |

| 4.7 | Straight Shank Cobalt Bits | 47 | 80 | |

| 4.76 | 3/16″ | Straight Shank Cobalt Bits | 52 | 52 |

| 4.8 | Straight Shank Cobalt Bits | 52 | 52 | |

| 4.9 | Straight Shank Cobalt Bits | 52 | 52 | |

| 5.0 | Straight Shank Cobalt Bits | 52 | 52 | |

| 5.1 | Straight Shank Cobalt Bits | 52 | 52 | |

| 5.16 | 13/64″ | Straight Shank Cobalt Bits | 52 | 52 |

| 5.2 | Straight Shank Cobalt Bits | 52 | 52 | |

| 5.3 | Straight Shank Cobalt Bits | 52 | 52 | |

| 5.4 | Straight Shank Cobalt Bits | 57 | 57 | |

| 5.5 | Straight Shank Cobalt Bits | 57 | 57 | |

| 5.56 | 7/32″ | Straight Shank Cobalt Bits | 57 | 57 |

| 5.6 | Straight Shank Cobalt Bits | 57 | 57 | |

| 5.7 | Straight Shank Cobalt Bits | 57 | 57 | |

| 5.8 | Straight Shank Cobalt Bits | 57 | 57 | |

| 5.9 | Straight Shank Cobalt Bits | 57 | 57 | |

| 5.95 | 15/64″ | Straight Shank Cobalt Bits | 57 | 57 |

| 6.0 | Straight Shank Cobalt Bits | 57 | 57 | |

| 6.1 | Straight Shank Cobalt Bits | 63 | 101 | |

| 6.2 | Straight Shank Cobalt Bits | 63 | 101 | |

| 6.3 | Straight Shank Cobalt Bits | 63 | 101 | |

| 6.35 | 1/4″ | Straight Shank Cobalt Bits | 63 | 101 |

| 6.4 | Straight Shank Cobalt Bits | 63 | 101 | |

| 6.5 | Straight Shank Cobalt Bits | 63 | 101 | |

| 6.6 | Straight Shank Cobalt Bits | 63 | 101 | |

| 6.7 | Straight Shank Cobalt Bits | 63 | 101 | |

| 6.75 | 17/64″ | Straight Shank Cobalt Bits | 69 | 109 |

| 6.8 | Straight Shank Cobalt Bits | 69 | 109 | |

| 6.9 | Straight Shank Cobalt Bits | 69 | 109 | |

| 7.0 | Straight Shank Cobalt Bits | 69 | 109 | |

| 7.1 | Straight Shank Cobalt Bits | 69 | 109 | |

| 7.14 | 9/32″ | Straight Shank Cobalt Bits | 69 | 109 |

| 7.2 | Straight Shank Cobalt Bits | 69 | 109 | |

| 7.3 | Straight Shank Cobalt Bits | 69 | 109 | |

| 7.4 | Straight Shank Cobalt Bits | 69 | 109 | |

| 7.5 | Straight Shank Cobalt Bits | 69 | 109 | |

| 7.54 | 19/64″ | Straight Shank Cobalt Bits | 75 | 117 |

| 7.6 | Straight Shank Cobalt Bits | 75 | 117 | |

| 7.7 | Straight Shank Cobalt Bits | 75 | 117 | |

| 7.8 | Straight Shank Cobalt Bits | 75 | 117 | |

| 7.9 | Straight Shank Cobalt Bits | 75 | 117 | |

| 7.94 | 5/16″ | Straight Shank Cobalt Bits | 75 | 117 |

| 8.0 | Straight Shank Cobalt Bits | 75 | 117 | |

| 8.1 | Straight Shank Cobalt Bits | 75 | 117 | |

| 8.2 | Straight Shank Cobalt Bits | 75 | 117 | |

| 8.3 | Straight Shank Cobalt Bits | 75 | 117 | |

| 8.33 | 21/64″ | Straight Shank Cobalt Bits | 75 | 117 |

| 8.4 | Straight Shank Cobalt Bits | 75 | 117 | |

| 8.5 | Straight Shank Cobalt Bits | 75 | 117 | |

| 8.6 | Straight Shank Cobalt Bits | 81 | 125 | |

| 8.7 | Straight Shank Cobalt Bits | 81 | 125 | |

| 8.9 | Straight Shank Cobalt Bits | 81 | 125 | |

| 9.0 | Straight Shank Cobalt Bits | 81 | 125 | |

| 9.1 | Straight Shank Cobalt Bits | 81 | 125 | |

| 9.13 | 23/64″ | Straight Shank Cobalt Bits | 81 | 125 |

| 9.2 | Straight Shank Cobalt Bits | 81 | 125 | |

| 9.3 | Straight Shank Cobalt Bits | 81 | 125 | |

| 9.4 | Straight Shank Cobalt Bits | 81 | 125 | |

| 9.5 | Straight Shank Cobalt Bits | 81 | 125 | |

| 9.52 | 3/8″ | Straight Shank Cobalt Bits | 87 | 133 |

| 9.6 | Straight Shank Cobalt Bits | 87 | 133 | |

| 9.7 | Straight Shank Cobalt Bits | 87 | 133 | |

| 9.8 | Straight Shank Cobalt Bits | 87 | 133 | |

| 9.9 | Straight Shank Cobalt Bits | 87 | 133 | |

| 9.92 | 25/64″ | Straight Shank Cobalt Bits | 87 | 133 |

| 10.0 | Straight Shank Cobalt Bits | 87 | 133 | |

| 10.1 | Straight Shank Cobalt Bits | 87 | 133 | |

| 10.2 | Straight Shank Cobalt Bits | 87 | 133 | |

| 10.3 | Straight Shank Cobalt Bits | 87 | 133 | |

| 10.32 | 13/32″ | Straight Shank Cobalt Bits | 87 | 133 |

| 10.4 | Straight Shank Cobalt Bits | 87 | 133 | |

| 10.5 | Straight Shank Cobalt Bits | 87 | 133 | |

| 10.6 | Straight Shank Cobalt Bits | 87 | 133 | |

| 10.7 | Straight Shank Cobalt Bits | 94 | 142 | |

| 10.72 | 27/64″ | Straight Shank Cobalt Bits | 94 | 142 |

| 10.8 | Straight Shank Cobalt Bits | 94 | 142 | |

| 10.9 | Straight Shank Cobalt Bits | 94 | 142 | |

| 11.0 | Straight Shank Cobalt Bits | 94 | 142 | |

| 11.1 | Straight Shank Cobalt Bits | 94 | 142 | |

| 11.11 | 7/16″ | Straight Shank Cobalt Bits | 94 | 142 |

| 11.2 | Straight Shank Cobalt Bits | 94 | 142 | |

| 11.3 | Straight Shank Cobalt Bits | 94 | 142 | |

| 11.4 | Straight Shank Cobalt Bits | 94 | 142 | |

| 11.5 | Straight Shank Cobalt Bits | 94 | 142 | |

| 11.51 | 29/64″ | Straight Shank Cobalt Bits | 94 | 142 |

| 11.6 | Straight Shank Cobalt Bits | 94 | 142 | |

| 11.7 | Straight Shank Cobalt Bits | 94 | 142 | |

| 11.8 | Straight Shank Cobalt Bits | 94 | 142 | |

| 11.9 | Straight Shank Cobalt Bits | 101 | 151 | |

| 11.91 | 15/32″ | Straight Shank Cobalt Bits | 101 | 151 |

| 12.0 | Straight Shank Cobalt Bits | 101 | 151 | |

| 12.1 | Straight Shank Cobalt Bits | 101 | 151 | |

| 12.2 | Straight Shank Cobalt Bits | 101 | 151 | |

| 12.3 | Straight Shank Cobalt Bits | 101 | 151 | |

| 12.30 | 31/64″ | Straight Shank Cobalt Bits | 101 | 151 |

| 12.4 | Straight Shank Cobalt Bits | 101 | 151 | |

| 12.5 | Straight Shank Cobalt Bits | 101 | 151 | |

| 12.6 | Straight Shank Cobalt Bits | 101 | 151 | |

| 12.7 | Straight Shank Cobalt Bits | 101 | 151 | |

| 12.7 | 1/2″ | Straight Shank Cobalt Bits | 101 | 151 |

| 12.8 | Straight Shank Cobalt Bits | 101 | 151 | |

| 12.9 | Straight Shank Cobalt Bits | 101 | 151 | |

| 13.0 | Straight Shank Cobalt Bits | 101 | 151 | |

| 13.1 | 33/64″ | Straight Shank Cobalt Bits | 101 | 151 |

| 13.49 | 17/32″ | Straight Shank Cobalt Bits | 108 | 160 |

| 13.5 | Straight Shank Cobalt Bits | 108 | 160 | |

| 13.89 | 35/64″ | Straight Shank Cobalt Bits | 108 | 160 |

| 14.0 | Straight Shank Cobalt Bits | 108 | 160 | |

| 14.29 | 9/16″ | Straight Shank Cobalt Bits | 114 | 169 |

| 14.5 | Straight Shank Cobalt Bits | 114 | 169 | |

| 14.68 | 37/64″ | Straight Shank Cobalt Bits | 114 | 169 |

| 15.0 | Straight Shank Cobalt Bits | 114 | 169 | |

| 15.08 | 19/32″ | Straight Shank Cobalt Bits | 120 | 178 |

| 15.48 | 39/64″ | Straight Shank Cobalt Bits | 120 | 178 |

| 15.5 | Straight Shank Cobalt Bits | 120 | 178 | |

| 15.87 | 5/8″ | Straight Shank Cobalt Bits | 120 | 178 |

| 16.0 | Straight Shank Cobalt Bits | 120 | 178 | |

| 16.5 | Straight Shank Cobalt Bits | 125 | 184 | |

| 16.67 | 21/32″ | Straight Shank Cobalt Bits | 125 | 184 |

| 17.0 | Straight Shank Cobalt Bits | 125 | 184 | |

| 17.46 | 11/16″ | Straight Shank Cobalt Bits | 125 | 184 |

| 17.5 | Straight Shank Cobalt Bits | 130 | 191 | |

| 18 | Straight Shank Cobalt Bits | 130 | 191 | |

| 18.26 | 23/32″ | Straight Shank Cobalt Bits | 130 | 191 |

| 18.5 | Straight Shank Cobalt Bits | 135 | 198 | |

| 18.84 | 25/32″ | Straight Shank Cobalt Bits | 140 | 205 |

| 19.0 | Straight Shank Cobalt Bits | 135 | 198 | |

| 19.05 | 3/4″ | Straight Shank Cobalt Bits | 135 | 198 |

| 19.5 | Straight Shank Cobalt Bits | 140 | 205 | |

| 20 | Straight Shank Cobalt Bits | 140 | 205 | |

| 20.64 | 13/16″ | Straight Shank Cobalt Bits | 140 | 205 |

What Percentage of Cobalt is Best in Drill Bits?

Cobalt drill bits are made of a steel alloy that contains 5% cobalt.

This cobalt content gives the drill bits a higher heat resistance than regular steel drill bits, making them ideal for use on harder metals.

In addition, the cobalt content helps to extend the lifespan of the drill bit and provides greater durability. If you regularly work with hard metals, investing in a set of cobalt drill bits is a wise choice.

With proper care, your cobalt drill bits will provide years of reliable service.

Cobalt Bits for Iron Drilling

Are Cobalt Drill Bits Good for Stainless Steel?

Cobalt drill bits are a type of cutting tool that is particularly successful in cutting through hard metals such as stainless steel and cast iron.

The cobalt in the bits helps to toughen and strengthen them, making them more resistant to wear. As a result, cobalt bits can last much longer than other types of bits, even when used on tough materials.

In addition, cobalt bits tend to produce less heat than other types of bits, which helps to extend their life even further.

While cobalt drill bits are more expensive than other types of bits, their longevity and performance make them a worthwhile investment for anyone who regularly works with hard metals.

Is Cobalt Stronger than Steel?

Cobalt drill bits offer a number of advantages over high-speed steel bits.

The cobalt content in these bits gives them additional strength and more durability, making them fast drilling on hard metals, stainless steels, and irons.

As a result, cobalt drill bits are an excellent choice for a variety of applications.

Cobalt Bits – Your Excellent Choice

Is Cobalt Better than HSS?

Cobalt drill bits are designed for drilling into harder materials such as stainless steel and cast iron.

The cobalt content in the steel helps to increase its heat resistance, making it ideal for repeated use with power tools.

In addition, cobalt bits retain their sharpness for longer periods of time, making them a good choice for high-usage applications.

| HSS Drill Bits Manufacturer Made From | |||||||||

| Hss Drill Bits Steel No. | Steel No. | CHEMICAL ANALYSIS (%) | |||||||

| C | Si | Mn | P | S | Cr | W | Mo | ||

| HSS Drill Bits 4241 | W4Mo2Cr4VSi | 0.9 | 1 | 0.3 | ≤0.030 | ≤0.015 | 4.8 | 1.6 | 0.65 |

| 1 | 1.3 | 0.4 | 5.1 | 1.85 | 0.8 | ||||

| HSS Drill Bits 4341 | W4Mo3Cr4VSi | 0.89 | 0.6 | 0.3 | ≤0.030 | ≤0.015 | 3.8 | 3.6 | 2.6 |

| 0.97 | 1 | 0.4 | 4.4 | 3.85 | 2.85 | ||||

| HSS Drill Bits 9341 | W9Mo3Cr4V | 0.78 | 0.2 | 0.3 | ≤0.030 | ≤0.015 | 3.8 | 8.6 | 2.8 |

| 0.86 | 0.4 | 0.4 | 4.4 | 8.9 | 3.05 | ||||

| HSS Drill Bits M2 | W6Mo5Cr4V2 | 0.81 | 0.2 | 0.3 | ≤0.030 | ≤0.015 | 3.8 | 5.6 | 4.6 |

| 0.89 | 0.45 | 0.4 | 4.4 | 5.85 | 4.85 | ||||

| Cobalt HSS Drill Bits M35 | W6Mo5Cr4V2 Co5 | 0.88 | 0.2 | 0.3 | ≤0.030 | ≤0.015 | 3.8 | 5.6 | 4.6 |

| 0.95 | 0.45 | 0.4 | 4.4 | 5.85 | 4.85 | ||||

| Cobalt HSS Drill Bits M42 | W6Mo5Cr4V2 Co8 | 1.05 | 0.15 | 0.15 | ≤0.030 | ≤0.015 | 3.5 | 1.15 | 9 |

| 1.15 | 0.65 | 0.4 | 4.25 | 1.85 | 10 | ||||

[toc]

Get A Quote Now !

Are Cobalt Drill Bits Worth it?

Cobalt drill bits are made with a cobalt alloy, which is harder and more durable than high-speed steel.

The cobalt content in the alloy (5-8%) gives the drill bit its toughness and resistance to heat. It can be used on a variety of materials, including hard metals, stainless steel, and cast irons.

Cobalt drill bits are also more wear-resistant than HSS bits and perform better at higher temperatures.

Cobalt Bits and HSS Bits

How Long are Drill Bits within Cobalt Drill Bits?

When it comes to drilling, there is no one-size-fits-all solution. The type of bit you need will depend on the material you’re drilling, the thickness of the material, and the size of the hole you need to make.

For example, cobalt bits are designed to drill through tough metals, while standard high-speed steel bits can be used for drilling wood and plastic. In general, longer bits are better for drilling through thick materials, while shorter bits are more suitable for thin materials.

However, it’s also important to consider the diameter of the bit. A larger bit will create a wider hole, while a smaller bit will be better for making precision holes.

Ultimately, the best way to choose the right drill bit is to consult with a professional or refer to a reliable guide.

By taking the time to select the appropriate bit, you can ensure that your project is completed successfully and with minimal damage to the material.