Diamond Core Drill Bit

- Your Trusted and Reliable Diamond Products Core Drill Manufacturer

- You get high-quality diamond products core drill bits.

- You can request customization of your diamond products’ core drill bits.

- All the products of Tenyu Tools come with a reasonable warranty period.

- You will experience the cutting-edge technology Tenyu Tools uses to manufacture their products.

- Only the highest-grade materials are used to produce diamond core drill bits.

- You get a guarantee that everything you purchase has no defects and flaws.

- You will enjoy amazing deals when you do business with Tenyu Tools, China’s leading manufacturer.

- Tenyu Tools is the leading diamond core bit manufacturers in China, Europe, North America, and other parts of the world.

- It has an ISO 9001-2000 quality management system authentication and TUV authentication.

Are You Up To the Challenge At Diamond Core Drill Bits?

Make Tenyu Tools your partner

As one of the most trusted diamond core drill manufacturers in China, Tenyu Tools can help grow your business.

Enjoy the perks and privileges of having Tenyu Tools as your drilling tool and saw blade suppliers.

Send inquiry now!

- Description For Diamond Products Core Drill

- Diamond Core Drill Features

- Suit

Diamond products core drill is a widely-popular tool in the construction, masonry, and manufacturing industries.

This diamond-tipped bit is the gold standard in coring or drilling operation.

It has an incredible capability to penetrate the hardest material or ground surface.

The robust nature of the diamond core drill bit delivers fast, precise, and efficient holes.

It can extract sample materials from the toughest environmental conditions with ease.

The diamond core drill bit features a hollow form.

The purpose of the design is to keep it cool during the drilling operation.

The coring motion generates heat and friction, so cooling it throughout the task is vital.

It also facilitates debris removal and prevents fissures or cracks in the material being drilled.

Diamond Products Core Drill Bits are Very Versatile

It can handle the toughest materials like hardwood, gemstones, rocks, ceramics, fossils, glass, and so on.

- For large drilling projects and concrete core drilling, this diamond-tipped drill bit is the best.

It can make up to 700mm holes.

Deeper drilling needs drill bit extensions.

- Small core drill bits are ideal for small jobs, jewelry making, and DIY projects.

Find 0.75mm to 3mm core drill bits for these types of applications.

Related Products Mention

Tenyu Tools is a perfect choice if you are looking for a dependable diamond core drill bit supplier.

It is the leading manufacturer of quality power tool accessories in China.

Tenyu Tools products include all types and sizes of drill bits, blades, and other non-standard tools.

Diamond Products Core Drill FAQ

Diamond products core drill is used for coring or cutting precise holes.

The diamond core drill bit is the gold standard in the construction and manufacturing industries.

Its ability to extract samples or penetrate the toughest surface material is remarkable.

Diamond products core drill works efficiently, quickly, and accurately.

Its robust nature is ideal for core sample extraction in the harshest environment.

During the drilling process, the drill bit delivers the optimum amount of friction and heat

But not all available diamond products core drill bits are made equal.

Diamond core bit manufacturers use different types of primary and secondary materials.

Finding the best bits can be a bit confusing with many choices in the market.

We got you covered with this ultimate guide that features all the essential information you need.

It’s like asking the diamond core drill manufacturers about the cutting edge of their products.

So, before going out to buy diamond products core drill bits in the nearest hardware, check this out.

You can choose between two types of diamond core drill bit?

- Sintered diamond core drill bit

It features a steel shank with several layers of diamonds.

The cutting edge of the bit is enhanced by the diamond grits, making it the most durable option.

To prolong its use and sharpness, regular dressing before and after use is necessary.

Sintered drill bits are extremely useful in drilling deep and precise holes.

- Electroplated or coated diamond core drill bit

This is the more economical option.

It comes with a nickel-bonded steel shank and a single layer of diamond grits.

Constant use can wear down the layer easily, necessitating a new purchase.

Nevertheless, it can drill like the sintered bits.

What is a Diamond Products Core Drill Bit?

Diamond products core drill bit is also known as diamond coring bit.

It is capable of creating 10mm to 60mm holes without leaving damage on the surface.

Small diameter drill bits deliver higher speed compared to large-sized bits.

Bits with higher RPM (revolution per minute) improve the drilling performance and surface finish.

The size of the diamond products core drill bits you need depends on the size of the holes.

It is crucial to use the right size to maximize the coring process and avoid hassles.

Having different sizes of core drill bits would make your tasks easier.

If you can’t find the size you need from local stores or suppliers, Tenyu Tools can help you.

You can order custom core sizes for you or your clients from them.

This China-based company is one of the best diamond core drill bit suppliers in Asia.

How Does Diamond Products Core Drill Bit Look Like?

Diamond products core drill bit has a hollow form.

It is specially-crafted to allow water to flow inside out and around the inner core during drilling.

The distinct design keeps it cool when performing as well as for easy removal of debris.

It also prevents shattering or cracking the material you are drilling due to friction and heat.

Keeping the diamond products core drill bit cool also prolongs its life.

Diamond products core drill bits typically have a drilling depth of 2” to 2-3/4” with 88mm diamond depth and 1” to 2” shaft.

What are the Different Kinds of Diamond Products Core Drill Bit?

Diamond products core drill bits can be classified into two:

- Electroplated (coated) diamond core drill bits

The diamond grits are bonded to the steel shank of the bit in a single layer using nickel.

The downside of this bit is once the layer wears away, you need to buy another one.

Electroplated diamond products core drill bit is more economical, hence its popularity.

- Sintered diamond core drill bits

The steel shank of sintered drill bits has several layers of diamond grits.

The multiple coating layers make these diamond products core drill bits more expensive.

They last longer but require regular dressing or cleaning before and after use.

Cleaning the bit with aluminum oxide rock will expose fresh diamond coating.

These diamond products core drill bits are best for stonemasons.

Where Do You Use Diamond Products Core Drill Bit?

Diamond products core drill bits are very versatile.

They are ideal for coring hard materials such as:

- gemstones, rock, minerals, pebbles

- porcelain, ceramic, tiles, glazed pottery, china, plates

- glass, fused glass, sheet glass, sea glass, beach glass

- very hard wood

- fossil, shell, bone, antler

Do not use diamond products core drill bits on soft materials like:

- softwoods

- soft plastic

- soft metal

- plaster

Soft materials and surfaces can cause the diamond particles in your bits to be clogged.

What are the Advantages of Using Diamond Products Core Drill Bit?

The diamond core cutting system is one of the most efficient and fastest drill operations.

The versatility of the diamond products core drill bit makes it the perfect tool for core cutting.

- It guarantees precision, quality, and speedy drilling performance.

- It does not leave residues or dust particles.

- It drills smoother holes.

- It guarantees a greater amount of concrete removal without the usual vibrations.

- It sustains the structural integrity of the material being drilled.

- It makes rebar and metal cutting possible.

- It works excellently in different materials, from natural stone to reinforced concrete.

- It performs in a relatively silent and non-disruptive manner.

- It eliminates the possibility of fractures and prevents spalling.

- It is one of the best core drill bits for your crafts and DIY projects.

With the correct diamond products core drill bit, you get clean, precise, and sharp openings.

You won’t be needing patches or any kind of repair after the operation.

What are the Prerequisites in Choosing Diamond Products Core Drill Bit?

To determine if the diamond product core drill bit is perfect for the task, choose carefully.

The basic rule of thumb when selecting a core drill bit is simple.

- Soft bonds for hard materials (makes drilling fast and hassle-free)

- Hard bonds for soft or abrasive materials (for long-lasting performance)

Here are the prerequisites:

-

The hardness of the material

Metal bonded sintered diamond products core drill bit is the best for:

o materials with high metal content

o ultra-hard precious/natural stones

o advanced ceramic materials

Nickel bonded electroplated diamond products core drill bit works well with:

o less expensive or softer materials like glass, tile, composites, and soft stones

-

Geometry and Density of the material

Consider the composition and properties of the material such as:

o brittleness

o diameter

o hardness

o shape

o size

Find durable, multi-purpose diamond products core drill bits so can maximize their use.

You may consider buying custom diamond drill bits for more advanced materials.

-

Cost of material

If you are drilling expensive materials, you want the best coring bits to prevent damage.

Diamond products core drill bits ensure minimal to no deformation or waste of material.

How Do You Use Diamond Products Core Drill Bit?

Diamond core drilling is an art and science.

To achieve your goal, it is important to use the correct size for your projects.

- Small diamond products core drill bits are perfect for making tiny precision holes.

It is the best choice for jewelry making or handcrafting purposes.

Look for diamond products core drill bit with a solid, flat tip to get the job done.

You can choose from 0.75mm to 3mm sizes.

- Large diamond-tipped core drill bits make accurate pipe holes, manholes, and so on.

Diamond products core drill bits are available in 3.5mm to 60mm and larger sizes.

Large diameter core drilling usually makes the standard 10mm to 700mm diameter holes.

Regular core drilling can use 1-foot long diamond products core drill bit.

For deeper drilling, you can use bit extensions.

For concrete core drilling, a diamond-tipped core drill bit offers great advantages.

It can easily break up concrete, accessing the ground beneath with less effort.

How Long Does a Diamond Products Core Drill Bit Last?

The lifespan of your diamond products core drill bit depends on various factors such as:

Speed

To maximize the use of the bits and minimize damage to the material, run your drill at the recommended speed.

The speed of the diamond products core drill bit should match the application and materials.

- Abrasive and soft materials can handle higher speeds.

- Dense and hard materials require slower speeds.

The diameter of your diamond products core drill also influences the drilling speeds.

- Large diamond drills need around 3 RPMs while smaller drills need higher speeds up to 150,000 plus RPM.

- The speed will vary with the drilling depth, the material being drilled, the hardness of the material, geometry, density, environment, and goal of the operator.

Density

A diamond products core drill bit that is used to drill tough materials is expected to last shorter.

Bits that are used for coring softer materials are expected to have a longer life.

Pressure

The pressure used to keep the diamond products core drill bit going is also a significant factor.

Applying the right amount of pressure will lengthen the life of your bits.

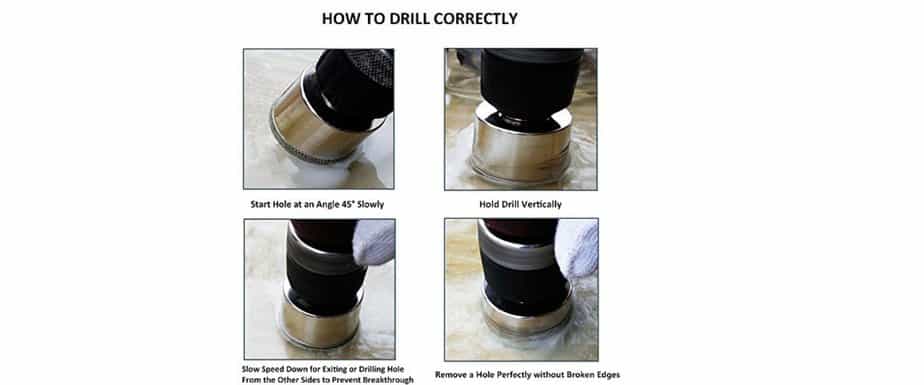

Starting slow prevents compromising your diamond products core drill bit.

- Begin with light to medium pressure or the lowest setting.

- As you feed the drill bit into the material, allow gradual speed and increase it

halfway.

- The drill will progress at its optimum speed.

Avoid increasing the pressure on your drill.

It will not reduce the completion time.

Instead, it will cause overheat and overload, leading to damage to the material.

It will also cause excessive wear on the diamond products core drill bit.

Never force the diamond drill to complete a hole.

- When near completion, it is best to reduce the pressure to minimize the chipping of the material.

- Apply even pressure to make the drill and material meet.

It helps the drill’s surface adjust to the material surface and becomes sharper.

Coolants

To ensure maximum use and keep the diamond bits from cracking, always keep them cool with water or coolant.

The most common reason for diamond products core drill damage is overheating.

It is vital to keep the diamond drill cool during the operation.

Excessive frictional heat can damage the diamond tip of the drill bit.

It also loosens up the metal matrix that keeps the diamond grits intact.

Never run a dry drill bit because it can turn the diamond grits into carbon.

This reverse osmosis process will damage your core drill bit.

You need to use water or coolant to lubricate the diamond product core drill bits.

Aside from keeping it cool, the coolant flushes out abrasive particles or debris during drilling.

The lubrication also keeps the drilling edge clean.

- Water is the best coolant as it delivers an excellent cooling effect at a minimal cost.

It does not leave the diamond product core drill greasy, oily, or contaminated.

The best water quality for the coring or drilling process is 90 psi or running water.

Check the diamond core bit manufacturers’ recommended water pressure.

It will optimize the cooling effect.

If you are going to use an additive, the right ratio should be considered as it may require a circulating system.

- Other types of coolants are mineral oils, synthetic water-soluble coolants, and lubricants

- Cold/compressed air – Coolant reduces friction between the diamond product core drill bit and material.

It can penetrate the micro-cracks that are generated during the impact of touching.

The surface tension of the coolant plays a crucial role in the drilling operation.

A coolant with lower surface tension easily enters the micro-cracks and wets the diamonds.

It promotes efficient removal of the debris while sustaining overall cooling effects.

How Many Holes Will a Diamond Products Core Drill Bit Make?

A single sintered diamond products core drill bit can give you about 1,200 holes.

An electroplated diamond core drill bit helps you make 80-120 holes.

The composition and density of the materials you drilled also contribute to the bits’ functionality.

One drill bit can drill up to 15 holes in china plates, or about 250 holes in sea glass.

How Deep Can You Drill Using a Diamond Products Core Drill Bit?

Most simple coring or drilling applications require not more than one-inch depth.

For deeper applications, it is vital to use running coolants from various directions.

A maximum amount of lubrication or water is necessary to keep the drill bit cool.

The spindle travel of the bit will limit its maximum drilling depth capability.

Make sure to check the spindle travel when buying your diamond products core drill bit.

The spindle travel refers to the distance your drill can move upward and downward before touching the surface.

To make deep holes that are beyond the drill bit depth, you can use tube extension.

Drill tube extensions lengthen the drilling depth and are available in different sizes.

Take note that longer drilling depths may require more than one diamond product core drill bit.

To ensure the safety of your diamond products core drill when drilling more than 1” depth, use multi-directional coolants

What to Do When Your Diamond Products Core Drill Bit is Having Issues?

While diamond products core drill bits are disposable, optimizing their functionality is in your hands.

The variables that affect their performance and lifespan can be contained to make them efficient.

A slight change in the speed, coolant direction, and feed rate can do the trick.

Matching the size and type of drill bits with the material’s density is also important.

When problems arise during the application, immediate action is necessary.

- If you smell burnt material, stop the operation.

It is possible that the speed of your diamond products core drill is too high.

Too much pressure can also cause the burning of the material being drilled.

It will also cause the drill bit to become dull, necessitating a new purchase soon.

To prevent it from happening, observe the right speed and pressure.

Keep your drill bit in optimum condition by applying coolant.

- If the diamond grits of the drill bits are falling away from the shank, reduce the pressure.

- If the diamond products core drill bit snaps, you are applying too much pressure.

The hardened steel shank only breaks when under extreme pressure, so lighten up.

How to Dress a Diamond Products Core Drill Bit?

Diamond products core drill bits can be retrued or dressed several times.

When your drill is “glazed,” you need to use great pressure to help it perform.

Dressing clears the “glazed” effect at the bottom of the bit.

It exposes a new layer of sharp diamond that makes the bit more efficient.

However, dressing or retrueing is a highly-sensitive task.

You need to take great care to prevent pulling out the diamonds from the diamond tip.

The best way to dress a diamond core drill bit is drilling a 6mm to a dressing stick.

Do it 2-3 times or up to 20 times when there is too much “glazed” issue.

While dressing the bit, keep your coolant flowing over the stick.

How Do You Know That Your Diamond Products Core Drill Bit Need Dressing?

There are various conditions that can alert you when you need to dress your diamond core bits.

It includes drilling conditions, depth of the hole, and materials being drilled.

The telltale signs are:

- Sound

When your diamond products core drill bit starts to generate a “shrill screech” sound, it needs dressing.

Immediately stop drilling and get the dressing stick.

The sound of a sharp diamond drill bit is “hissing.”

- Time cycle

Excessive drilling cycle affects the drill with too much pressure.

When you feel it, stop drilling and dress your diamond products core drill bit.

- Pressure

When you feel that your drill needs additional pressure to optimize the performance, stop.

Your drill bit needs dressing to regain its normal required pressure.

How to Maintain Your Diamond Products Core Drill Bit?

To get the value of your investment, proper care and maintenance are vital.

You need to sustain the shape and rigidity of the diamond section shape.

Regularly check the tip to guarantee that your diamond products core drill bit is optimized.

Make sure that the drill bit is not losing its roundness and sharpness.

Dressing to expose the cutting edge of the diamond in the bit should be regular.

It is also necessary to periodically check the inside of the diamond products core drill.

This is to ensure that there is no material clog.

When there is a clogged core, immediately wash the debris with water or other coolant sources.

What are the Safety Tips When Using a Diamond Products Core Drill Bit?

Always protect yourself by wearing eye and hearing protection.

For dry drilling, a respiratory mask is a must.

Moreover, improper use of diamond products core drill can cause personal injury.

To prevent it, observe the following precautions:

- Check the drilling tool or machine before using it.

- Make sure that everything is fitted to the right area.

- Check the plugs and electrical cords (if applicable).

- Use the correct diamond products core drill bit for the type of drilling operation.

- Make sure that the shaft of the drill is secured tightly.

- Do not use tools that seem slightly damaged.

- Have a first aid kit and a fire extinguisher nearby for emergency purposes.

Where Can You Find the Best Diamond Products Core Drill Bit Supplier?

The success of your business depends a lot on the reliability of your supplier.

If you are looking for a trusted diamond products core drill supplier, Tenyu Tools is an excellent choice.

It is one of the best diamond core drill manufacturers in the world.

Known for manufacturing quality products, Tenyu Tools offers amazing deals for their partner-suppliers.

They have been partnering with many importers, wholesalers, and distributors.

Tenyu Tools is now serving North America, Eastern Europe, Northern Europe, and China’s domestic markets.

They offer high-quality diamond products core drill bits and other accessories at fair prices.

All products come with a reasonable warranty period and delivered fast.

Why Tenyu Tools is the Best Diamond Products Core Drill Supplier?

If your goal is to upscale your business and try both the domestic and global market, Tenyu Tools got your back.

It is one of the biggest and most popular China-based manufacturers of diamond products core drill.

They can help you grow your export or distributorship business fast.

You get access to quality and durable products that are very much in demand in the manufacturing and construction industries.

Tenyu Tools can handle large volumes of orders and allow customization if necessary.

If you are interested in getting Tenyu Tools as a supplier of diamond products core drill bits, call them now.

Now is the time to scale up your own business.

If you have other questions regarding the diamond core drill bits, don’t hesitate to call Tenyu Tools.