Ever felt the frustration of splintered wood when trying to drill a clean hole? I know I have! Choosing the wrong drill bit can turn a simple project into a messy headache, wasting both time and precious materials.

Step drill bits can be used on wood, but they aren’t the ideal choice. These bits are specifically designed for thin materials like sheet metal and plastic where creating precise, clean holes is essential. For wood, you’ll generally get better results using brad point bits or spade bits instead.

Now, we’ll explore what they can and can’t do, and help you understand when they should – or definitely shouldn’t – be your go-to tool. This will help you make informed decisions and get the best results for your projects.

Can a Step Bit Drill through Steel?

Does your drill bit1 keep getting stuck when you’re trying to drill through a sheet of steel2? I’ve seen many DIYers3 run into this issue. It’s a common mistake to use the wrong type of drill bit for the job.

Yes, step drill bits can cut through steel, but they’re really only suitable for thin sheets, typically up to 1/4 inch thick. For thicker steel, you’ll need to switch to cobalt or titanium-coated twist drill bits. Using cutting oil will also improve your results and extend the life of your bits.

Understanding the Limits of Step Bits on Steel

To give you a clearer picture, here’s a quick guide to the maximum thickness a step bit can effectively handle for different materials:

| Material | Maximum Thickness |

|---|---|

| Mild Steel | 1/4" (6mm) |

| Stainless Steel | 1/8" (3mm) |

| Aluminum | 3/8" (10mm) |

I always tell my customers there are some important techniques to consider:

- Control Your Speed: Drilling steel requires a slow and steady approach. Aim for a speed between 100 and 300 RPM. High speeds generate excessive heat, which can quickly dull your bit.

- Lubricate, Lubricate, Lubricate: Cutting oil is your best friend when working with steel. It reduces friction and heat, allowing for a cleaner cut and prolonging the life of your drill bit. Apply it generously and frequently.

- Let the Bit Do the Work: Avoid applying excessive pressure. Forcing the bit can cause it to overheat, break, or wander off course. Let the cutting edges do the work at their own pace.

- Invest in Quality: Cheap drill bits might seem tempting, but they often lack the durability and precision needed for steel. Investing in high-quality, carbide-tipped step drill bits will save you money in the long run, as they last longer and perform better.

I remember one particular instance where a customer of mine went through three low-quality drill bits in a single attempt to drill through a thin sheet of stainless steel. After switching to one of our premium carbide step drill bits, he was able to complete over 200 holes with the same bit! The right tool really makes all the difference.

Are Step Drill Bits Good for Plastic?

Does that clear acrylic sheet crack every time you try to drill a hole in it? It’s a common problem when using the wrong drill bit on plastic. The material is brittle and requires a delicate touch.

Step drill bits are generally a good choice for drilling plastic, especially thin sheets. The way they gradually cut prevents the plastic from cracking or chipping. However, for thicker plastic blocks, regular twist drill bits can sometimes be more effective, as they are designed to bore through thicker materials.

Mastering the Art of Drilling Plastic

To help you achieve clean, professional-looking holes in plastic, here’s my advice:

-

For Thin Plastic Sheets (1/8" or thinner):

- Step drill bits are an excellent choice. Their gradual cutting action minimizes the risk of cracking or chipping.

- You’ll get clean, precise holes every time.

-

For Thicker Plastic Blocks:

- Regular twist drill bits can be used effectively, but you need to exercise caution.

- Drill slowly to prevent the plastic from melting due to friction.

- It’s a good idea to back the piece of plastic with a piece of wood. This will provide support and reduce the likelihood of the plastic cracking as the drill bit exits.

I always recommend keeping your drilling speed4 below 1,000 RPM when working with plastics. Excessive heat can cause the plastic to melt, resulting in a messy, uneven hole. Our customers have reported great success using step drill bits for a variety of plastic applications, including dashboards, signs, and display cases. The key is to go slow and let the bit do the work.

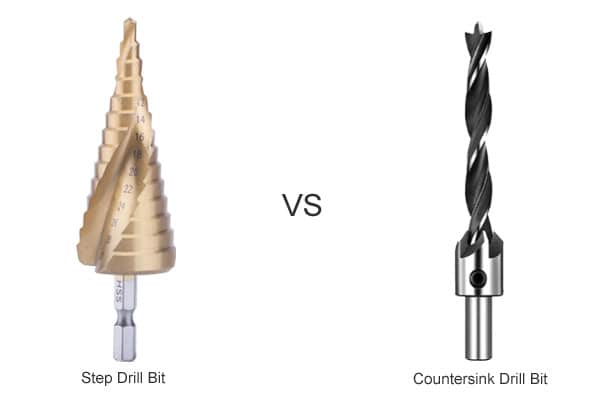

What is the Difference Between a Step Drill Bit and a Countersink Bit?

Are your screw heads sticking out awkwardly, preventing a flush finish? Are you unsure which type of bit to use to achieve that professional, seamless look? Many people get these two types of bits confused.

Countersink bits are designed to create a conical, angled hole that allows the head of a screw to sit flush with the surface of the material. Step drill bits, on the other hand, create straight, stepped holes of varying diameters. While both types of bits can be used to enlarge existing holes, their primary purposes are quite different.

Countersink vs. Step Drill Bit: Choosing the Right Tool

To make the differences clearer, here’s a table outlining the key features and applications of each type of bit:

| Feature | Countersink Bit | Step Bit |

|---|---|---|

| Main Purpose | To create a recess for screw heads | To enlarge holes in steps |

| Hole Shape | Conical | Cylindrical with steps |

| Best For | Woodworking, creating flush surfaces | Sheet metal, plastic, electrical work |

| Common Uses | Furniture making, cabinet construction | Drilling electrical boxes, HVAC work |

| Cutting Edges | Typically 1-3 | Multiple (one per step) |

I recall a conversation with a cabinet maker who sources both countersink and step drill bits from my company. He explained that he primarily uses countersink bits for creating a clean, professional look when installing visible screws in furniture. Step drill bits, on the other hand, are his go-to choice for enlarging holes5 to accommodate hinges and other hardware. Understanding the nuances of each tool is essential for achieving high-quality results6.

What is the Difference Between a Drill Bit and a Step Drill Bit?

Do you need to make a hole, but feel overwhelmed by the sheer number of drill bit types available? It’s a common dilemma. Each type of bit is designed for a specific purpose, and choosing the right one can make all the difference.

Regular drill bits are designed to create holes of a single, fixed diameter. Step drill bits, in contrast, allow you to create holes of multiple sizes with a single tool. Step drill bits are generally better suited for working with thin materials, while regular drill bits are more effective for drilling through thicker materials.

Selecting the Perfect Drill Bit for Your Project

To help you navigate the world of drill bits, here’s a table outlining some common job types and the recommended drill bit for each:

| Job Type | Recommended Bit | Reason |

|---|---|---|

| Drilling wood over 1/2" thick | Brad point bit | Creates clean entry and exit holes, minimizing splintering |

| Drilling metal sheets | Step drill bit | Allows for drilling multiple hole sizes with one bit, prevents the bit from catching |

| Drilling concrete | Masonry bit | Features a carbide tip designed to withstand the abrasive nature of concrete |

| Drilling tile | Glass/tile bit | Prevents cracking and chipping of delicate tile surfaces |

| General-purpose drilling | Twist bit | A versatile option suitable for a wide range of materials and applications |

Our factory produces both standard drill bits and step drill bits. From my experience, professional tradespeople typically purchase step drill bits for their metalworking projects, while they tend to rely on standard drill bits for most other materials. DIY enthusiasts often appreciate the versatility of step drill bits7, as they can be used for a variety of small projects around the home.

Conclusion

Always take the time to choose the right drill bit for the job. Step drill bits are excellent for thin metals and plastics, but other types of bits are better suited for wood and thicker materials. Selecting the right bit will save you time, money, and frustration.

-

Understanding the right drill bit for steel can save you time and frustration. Explore this link to find the best options available. ↩

-

Discover effective techniques for drilling through steel to ensure a smooth and successful project. This link offers practical tips. ↩

-

Learning from the mistakes of others can help you avoid pitfalls in your projects. Check out this resource for valuable insights. ↩

-

Understanding the optimal drilling speed can help you avoid damaging materials and ensure clean results. ↩

-

This resource will provide techniques and tips for enlarging holes accurately, ensuring a perfect fit for your hardware. ↩

-

Discover expert advice on drilling techniques that lead to high-quality results in your projects. ↩

-

Explore this link to understand how step drill bits enhance precision and efficiency in metalworking projects. ↩