Coating a thin layer of refractory metal with good wear resistance on the surface to obtain the coated High Speed Hacksaw Blades

It is a high-speed steel substrate with good strength and toughness by vapor deposition

The Coating Advantage of High Speed Hacksaw Blades

- Reducing thermal diffusion and chemical reactions between the saw blade and the work piece

- It has high surface hardness, good wear resistance, stable chemical properties, heat and oxidation resistance, low coefficient of friction, and thermal conductivity

- Low-level characteristics can increase the blade life several times compared to uncoated saw blades during cutting

Therefore, coated saw blades have become the symbol of modern cutting saw blades

Full-speed hacksaw blade, white steel color, is uncoated saw blade, cutting general non-ferrous metals, such as brass, aluminum, etc

There are 6 Types Coating of High Speed Hacksaw Blades

Nitriding Coating (Black) VAPO

- Nitriding coating is subjected to high-temperature oxidation heat treatment, and the color is dark black

- After the chemical element Fe3O4 is precisely and specially heat-treated, an oxide layer (Fe3O4) is formed on the surface

- Micron, surface hardness is about 800-900HV, friction coefficient: 0.65

This kind of saw blade has good surface smoothness, which helps to enhance the self-wetting ability of the saw blade

The phenomenon that the saw blade is caught by the material can be avoided to a certain extent

Due to its mature processing technology and high cost performance, the product is use widely in the market

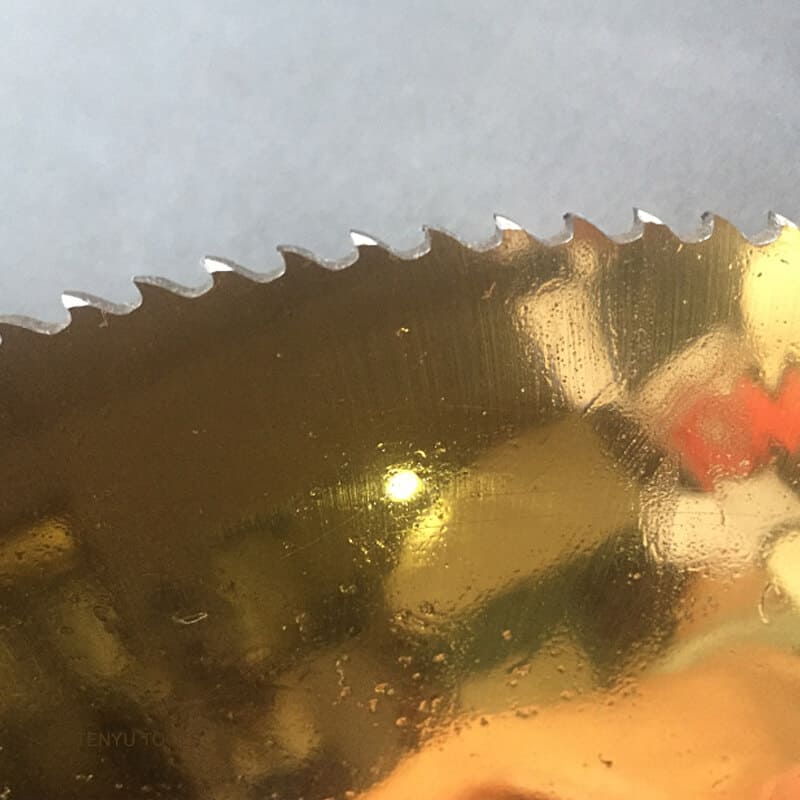

Titanium Nitride Coating (Gold) TIN

- After PVD nitrogen titanium treatment, the thickness of the saw blade coating is about 2-4 microns

- Its surface hardness is about 2200-2400HV, friction coefficient: 0.55, cutting temperature: 520 ° C

This kind of saw The blade can greatly increase the use time of the saw blade

In order to make full use of its characteristics, the cutting speed should increase reflect its value

The main function of this coating is to make the saw blade more resistant to cutting

For the cutting of general materials, its excellent performance can effectively improve the cutting speed and reduce the loss

CrN Coating (Short for Super Coating) CRN

- This coating is particularly resistant to adhesion, corrosion and oxidation

- The coating thickness of the saw blade is 2-4 microns, the surface hardness is 1800HV

- The surface hardness is 1800HV, the cutting temperature is lower than 700 ° C, and the color is metallic gray

It is highly recommended to use when cutting copper and titanium

The coating process has no impact on the environment

Suitable for cutting copper, aluminum and other materials, with high coating density and surface hardness, and the lowest friction factor of all coatings

Titanium Nitride Aluminide Coating (Color) TIALN

- This is a new multi-layer anti-wear coating

- The saw blade treated with multi-layer PVD coating has achieved a very low coefficient of friction

- Its surface hardness is about 3000-3300 HV. Friction Coefficient: 0.35, Oxidation temperature: 450 ℃

This kind of saw blade can make the cutting surface very smooth, the saw blade is more wear-resistant

It is recommended that the cutting speed and feeding speed are relatively high and the cutting tensile strength exceeds 800 N / mm2, such as Stainless steel, etc., are used under particularly harsh working conditions

Aluminum Titanium Nitride Coating (Super A Coating for short) ALTIN

- This is a new multilayer composite anti-wear coating

- The thickness of this coating is 2-4 microns, surface hardness: 3500HV, friction coefficient: 0.4, cutting temperature

- Below 900 ° C, recommend you to use materials with high cutting speed and feed speed and cutting tensile strength exceeding 800 N / mm2

It is used under particularly severe working conditions such as dry cutting

Due to the toughness and good physical stability of the aluminum titanium nitride coating, the saw blade is more wear-resistant and suitable for cutting all steels

Due to its low friction coefficient and low thermal conductivity, it is especially suitable for dry cutting at high speed and high temperature

Titanium Carbonitride Coating (Bronze) TICN

- This is a coating suitable for more demanding wear resistance requirements

- It is recommended to cut materials with tensile strength exceeding 800 N / mm2

- The thickness of the coating is 3 microns, the coefficient of friction is 0.45, the oxidation temperature is 875 ° C, and its surface hardness is about 3300-3500HV

It is suitable for cutting high-strength steels such as stainless steel

It is also for cutting softer materials such as cast iron, aluminum alloy, brass, and copper

Due to its low friction coefficient and low thermal conductivity, it is particularly suitable for high speed and high temperature dry cut

High Speed Hacksaw Blades Coating in Summary

The coating not only can it increase the appearance, but also increase the durability of the saw blade to a greater extent

The above are the six coating materials, if you know more about the drill bits and saw blades, click here.