Slugger Annular Cutter Manufacturer

- Reasons Why You Should Choose Tenyu Tools’ Slugger Annular Cutters

- All the custom Slugger Annular Cutters you need can be shaped to specific sizes and dimensions

- You’ll be able to work on and cut steel and metal three (3) times faster than regular bits

- You can choose to have it made from either TCT or HSS

- You’ll be able to use it on all types of magnetic drills and press drills

- You can get tough and carefully-analyzed designs for your Slugger Annular Cutterbits

- You’ll never overpay – we’ll give you a free estimate even before we begin production

- You will ALWAYS get your orders on time – even earlier than what’s expected!

- Your Slugger Annular Cutters will be delivered in perfect condition, thanks to packaging

Business Advantages of Working Slugger Annular Cutter With Tenyu Tools Co., Ltd.

Slugger Annular Cutter – The Comprehensive FAQ Guide

When you hear “Slugger Annular Cutter,” what is the first thing that comes to mind? A lot of people will think about a baseball bat, but is that right?

It actually is not correct; in fact, Slugger Annular Cutters are actually annular cutters, in just a different term. In today’s guide, we will enlighten you about what a Slugger Annular Cutter is, how you can use it to your advantage, and where the best place is to find the best and the highest quality of Slugger Annular Cutters in the market.

Understanding What a Slugger Annular Cutter Is

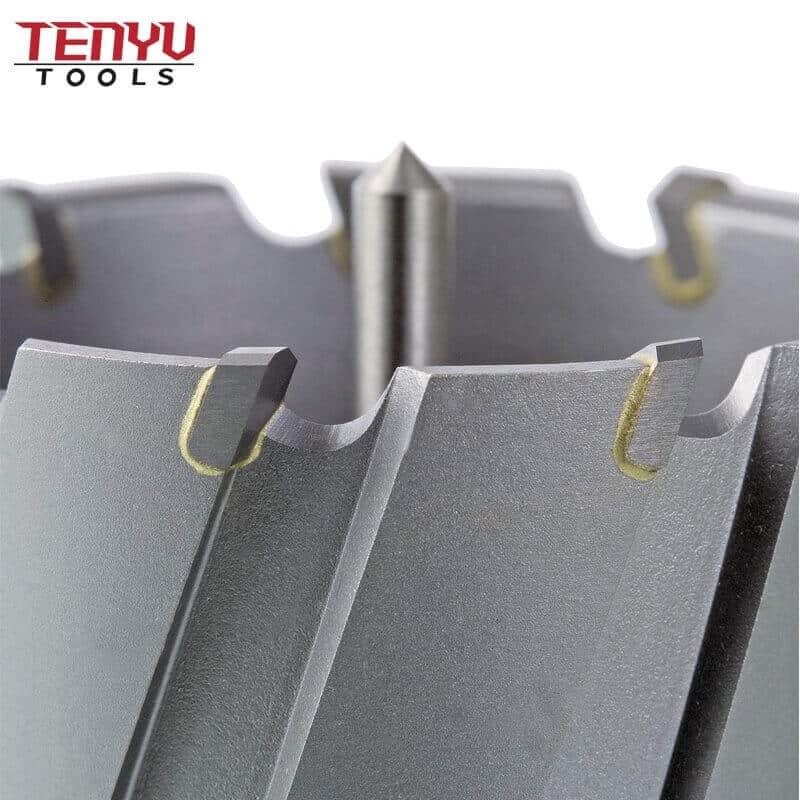

To help you understand further, Slugger Annular Cutters are also annular cutters or slugger bits, it’s just a different term. Many people say that it’s also the same with hole saws, just a different type.

Image of a hole saw that they say is the same as a Slugger Annular Cutter

This term is thrown around in the labor industry as it’s distinct to hear “Slugger Annular Cutters,” than annular cutters.

So, they’re the tools you use if you want to cut or slice through steel, metal, aluminum, copper, brass, or any other type of hard or touch metal. Usually, you use them if you’re looking to create a hole that runs through the other side of the workpiece; and if you want to cut a large-diameter hole.

Can Slugger Annular Cutters Drill Faster Than a Twist Drill Bit?

Yes, as a matter of fact, it’s textbook knowledge that slugger annular cutters are capable of drilling or cutting faster than the regular or the traditional twist drill bit.

Yes, Slugger Annular Cutter bits drill and cut material faster than twist drill bits

They cut three (3) to five (5) times faster and you can use them without putting too much pressure on the drill or the handle of your press machine.

Plus, larger holes would be created faster, too!

What’s the Standard Material Used to Produce Slugger Annular Cutters?

The core in creating and in making slugger annular cutters are versatile and flexible. As a matter of fact, many manufacturers use a wide array of materials to produce it.

To give you some of the most customary ones, they include:

- High-Speed Steel (HSS)

- HSS with Cobalt Coating

- HSS with TiN (Titanium Nitride) Coating

- Tungsten Carbide Tipped (TCT) Material

But of course, manufacturers and suppliers continuously experiment to find out what other types of materials work in terms of the creation of the manufacturing of slugger annular cutter bits.

How Do You Drill Using Slugger Annular Cutters?

Drilling a hole using slugger annular cutting bits isn’t actually different or far from how you would drill using a conventional twist drill bit.

You can drill it as simple as how you would drill using a twist bit

The only main difference, in terms of how we’ll teach it, would be with the drill used (magnetic press drill).

Preparation and Mounting

First things first – is your machine prepared for the procedure you are about to partake in? Ensure that your machine is ready by checking if the Slugger Annular Cutter bit is the correct type and size for the workpiece.

Then, check if you have an ejector pin. You shall never use a Slugger Annular Cutter without an ejector pin.

Afterward, set your device up by setting the speed (RPM) and by pouring coolant in the tank. The coolant will serve as the internal lubricant of the cutting process.

What you have to do next is to carefully mount the Slugger Annular Cutter drill bit onto the chuck of the press drill. Make sure that the ejector pin is there and that it’s chucked and positioned without moving or loose ends.

Now, we’re ready to drill!

Initial Drilling

Now we get to the initial drilling stage. Unlike regular twist drills where you’d have to apply pressure to get the cut, you just need to let the Slugger Annular Cutter touch the surface of the workpiece initially.

Start drilling at a low feed rate at first; increase to moderate when it penetrates the workpiece completely.

With light pressure, carefully adjust the handle to slowly and lightly push the head of the drill down, assisting the cutter to where it should be.

Should the workpiece be 50 mm thick, help and aid the drilling by applying some external lubricant.

Aftercare or Maintenance

Now that you’re done with the cutting, you have to make sure that you care for your Slugger Annular Cutter drill bits appropriately.

- Avoid leaving any kind of debris or fragments on the cutting edges or the flutes

- Use a wipe cloth to clean it off. You can use a lubricant to help with the cleaning

- Store them where they would neither be scratched nor damaged by other materials

- NEVER leave the Slugger Annular Cutterattached to the chuck

So, using a slugger annular cutter isn’t so bad after all, right? It’s just akin to how you utilize a twist drill bit! The difference is only with the mag press drill!

Slugger Annular Cutter vs. Broach Cutters: Are They the Same?

Yes, a broach cutter bit is another term for annular Slugger Annular Cutters or core drills.

It’s mostly used in the construction and the structural industry because “sluggers” and “annular” are jargon for other equipment and materials too!

So, the next time you encounter the term, don’t be confused!

Who Makes the Best Slugger Annular Cutters?

The industry is filled with a ton of Slugger Annular Cutter manufacturers and suppliers. But, there are some that stand out!

Based on the most recent client demand, the following Slugger Annular Cutters are the most bought individually:

- S&F Stead & Fast annular cutters

- Accusize Industrial Tools (AIT) annular cutters

- ACTOOL HSS annular cutter

- JESUS Weldon shank Slugger Annular Cutter

NOTE: These are based on consumer demand, not a business. Meaning, they’re the “most sold” in hardware stores and online individually.

If you’re looking for a Slugger Annular Cutter to help you with the supply and the inventory for your business, or if you plan on buying slugger annular cutters wholesale, don’t think twice in choosing to work with us here at Tenyu Tools Co., Ltd. We are the best and the most trusted here in China!

We’ll discuss more about that below – for now, let’s answer more frequently asked questions!

How Are Slugger Annular Cutters Made and Manufactured?

The manufacturing procedure of Slugger Annular Cutters is ideally similar to how twist drill bits are made.