Twist Drill Manufacturers

- Why Trust Tenyu Tools Co., Ltd. as Your Twist Drill Bit Manufacturer?

- You can get consistency in the quality of your twist drill bits

- Tenyu Tools Co., Ltd. can manufacture custom twist drill bits

- All our twist drill bits are made with accuracy and precision

- You can get twist drill bits in the wholesale prices and rates!

- The twist drill bits you can get are manufactured by the best engineers and experts!

Get Your Reliable Twist Drill Manufacturers To Rocket Your Business

Tenyu Tools Co., Ltd. is China’s top choice when it comes to twist drill bits.

Whether you need an N-sharped 135-degree point angle; a 130-degree angle, or even a 118-degree point angle, you can count on us!

All the twist drill bits Tenyu Tools manufacture are all of the high quality with maximum lifespan and durability.

You can order cobalt drill bits, black oxide drill bits, HSS tapered bits and many more!

- You’ll be able to save up on costs because of the long life and durability of our bits

- Capable of working on copper, aluminum, steel, and metal sheets

- Most of our twist drill bits have universal round shanks

- Tenyu Tools’ twist drill bits will definitely save you time; we have bits that have drilling rates that go upwards of 40%

- You’ll never worry about friction – our finished twist drill bits are fined with the best polishing procedures

- The twist drill bits that we offer here at Tenyu Tools Co., Ltd are all made to perfection.

Business Advantages of Choosing Us as Your Twist Drill Bit Manufacturer

Tenyu Tools Co., Ltd. never failed in delivering the quality of twist drill bits to our clients.

We have an excellent research & development team to cater to your needs

- We have ISO, CE, and SGS certifications

- We have over a thousand clients who continue to trust and bank on us

- We have, under our employ, the best and the most trusted engineers and experts

- We can customize the twist drill bits you need

Reach Out to Us Today!

Can’t find the twist drill bit manufacturer you can bank and lean on? Contact and work with us here at Tenyu Tools Co., Ltd. and forget about other manufacturers!

Shoot us an email and we will gladly respond to your queries within 12 hours – that’s a guarantee!

Get the best service you can get from the most reliable and the most trusted twist drill bit manufacturer in China!

Send us your inquiry!

- Features and Benefits of Twist Drill Manufacturers

Choosing Tenyu Tools Co., Ltd’s twist drill bits can get you the following benefits and advantages:

Applications of Our Twist Drill Bits

The twist drill bits that we offer are flexible and versatile.

Our drill bits can be used in a wide variety of applications

They’re versatile in the sense that you can use them for a wide range of materials such as wood, plastic, concrete, steel, metal, and glass!

Wait, there’s more!

We here at Tenyu Tools are open to doing business with resellers, retailers, merchandisers, and other manufacturers!

We’re open to providing world-class quality products and services to those who trust us!

Twist Drill Bit Manufacturers – The Comprehensive FAQ Guide

Nowadays, choosing the manufacturing company for your twist drill bits is a challenge.

Apart from the fact that there are already a lot, the prices are becoming more competitive. If you’re looking for the best twist drill bit manufacturer, you’re in the right post.

Today, we’ll be discussing twist drill bits and their manufacturers in an in-depth fashion; that, by the end of the guide, you’ll know where to go and who to trust!

The Different Point Angles of Twist Drill Bits

Different manufacturers create varying angle degrees of twist drill bits.

The different angles mean different types of application – and they include:

- 118 degrees

- 130 degrees

- 135 degrees

You’d want to use a 118-degree twist drill bit if you want aggressive cuts. More so, this is what you’ll need if you are to work on soft materials like wood and paper. It can cut through steel, but it will dull quickly because of the steepness of the degree.

The 130-degree point angle is what you want if you’re looking to cut through semi-hard materials such as plastic, ceramics, etc. It’s made for harder materials than wood, but not as hard as steel.

Lastly, the 135-degree twist drill bit point angle is what you need to cut through or penetrate steel.

Color-Coding of Different Twist Drill Manufacturer

Many twist drill bit manufacturers assign colors to the different classifications of twist drill bits.

But, it is important to note that the different color-coding of twist drill bits do not dictate the quality or the performance they give.

Generally, HSS twist drill bits, that are often fully ground, are white in color. Nitrided drill bits or black oxide drill bits are coated with a chemical composition, developing the strength and the overall durability of it.

Cobalt drill bits usually appear in a dull golden color – almost yellowish brown.

While there are a lot of colors to choose from, they often do not have any bearing on the performance and the quality of the drill bit.

Can You Cut Steel With Twist Drill Bits?

Yes! As mentioned above, a 135-degree point angle twist drill bit is perfect for cutting hardened materials – which includes steel, among others.

The twist drill bit is used to cut through a thick portion of the steel

Many twist drill bit suppliers make varying angles to be able to provide a vast array of clients. So, you wouldn’t have to worry about where to find varying angles of twist drill bits.

Can You Sharpen Titanium Twist Drill Bits?

Akin to other types of drill bits, you can sharpen and re-sharpen titanium twist drill bits.

Twist drill bit being sharpened by a person/worker using a grinding wheel

However, it’s not the most ideal to do so. In fact, doing so runs the risk of your titanium drill bit to lose its coating, which also translates to losing heat resistance and strength.

Different Processes on How Twist Drill Bits are Made?

Twist drill bit manufacturers perform different procedures and manufacturing techniques in producing twist drill bits.

The process they’ll use will depend on the kind of drill bit you want, the material used, and the results sought after by their clients.

Twist drill bits are manufactured via the following processes:

Roll Forged

Also called hot forge rolling, it’s a manufacturing process where the raw material is fed through two (2) distinctive-shaped rollers, creating the twist drill bit.

In roll forging, the material worked on is heated up to a certain temperature.

Milled

The process of milling, on the other hand, utilizes a rotary cutter, removing bits and parts of materials, creating the drill bit.

Fully Ground

Lastly, grinding can also be a procedure to create twist drill bits.

It uses a grinding disc as the cutting tool, creating specific angles and grooves on a workpiece.

Those are the three (3) primary procedures used by twist drill bit suppliers in creating and producing twist drill bits.

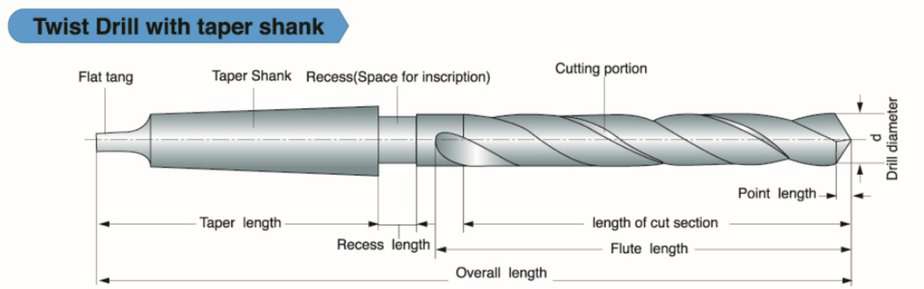

What is a Tapered Shank Twist Drill Manufacturers?

It’s a type of tool – drill bit – that is specifically made to match a tapered holder.

Its main use is to be able to fit holders that are tapered.

Unlike regular shanks that run straight, a tapered shank would help you in fitting it even in narrow and shallow holes.

How Does a Twist Drill Bit Function?

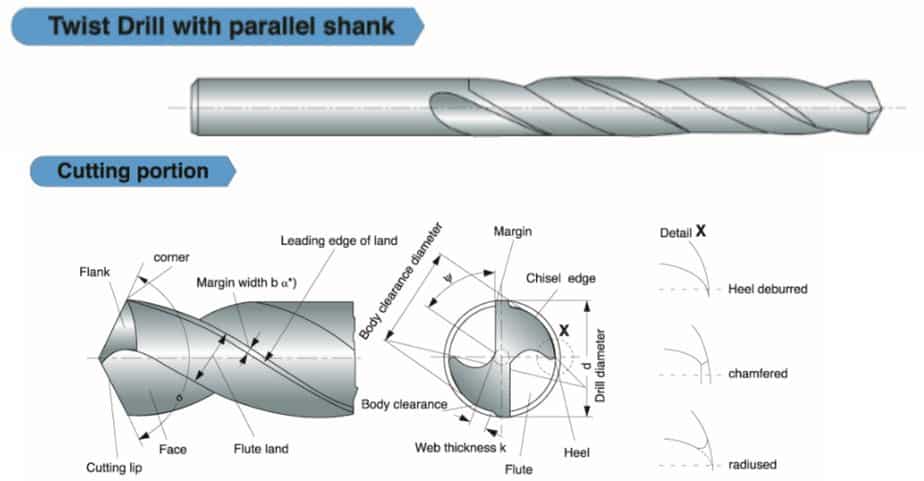

Twist drill bits are rotating cutters that have two (2) flutes and two (2) cutting edges.

A bit, when inserted into a drill, is used for material removal

The flutes are formed within the body, providing the cutting lips and permitting chip removal.

Using a power drill, the bit rotates and removes material. The rotating motion allows the bit to remove and cut parts of the material.

What Materials Are Used to Manufacture Twist Drill Bits?

Creating twist drill bits isn’t just limited to a single material.

As a matter of fact, manufacturers use a wide array of steel types to create and manufacture twist drill bits.

They use carbon steels and/or high-speed steels or (HSS). When it comes to the coating, there’s cobalt, zirconium, carbide tipped, titanium, and many more!

The quality of the bit will depend not only on the material; the procedure also has an effect on the final result it.

Parts and Anatomy of a Drill Bit

Twist drill bits might be small, but they’re packed with a lot of different parts.

Contrary to what most people believe in, twist drill bits aren’t just small steel tool parts. As a matter of fact, its complex composition makes it the more useful.

The parts of a twist drill bit includes:

- Shank

- Neck

- Flute/s

- Land

- Web

- Cutting Edge

Those are what make up a twist drill bit. Knowing them can help you with a lot of things, especially when you are about to make the purchase.

You’d know what to find, the type and the characteristic of a twist drill bit, etc.

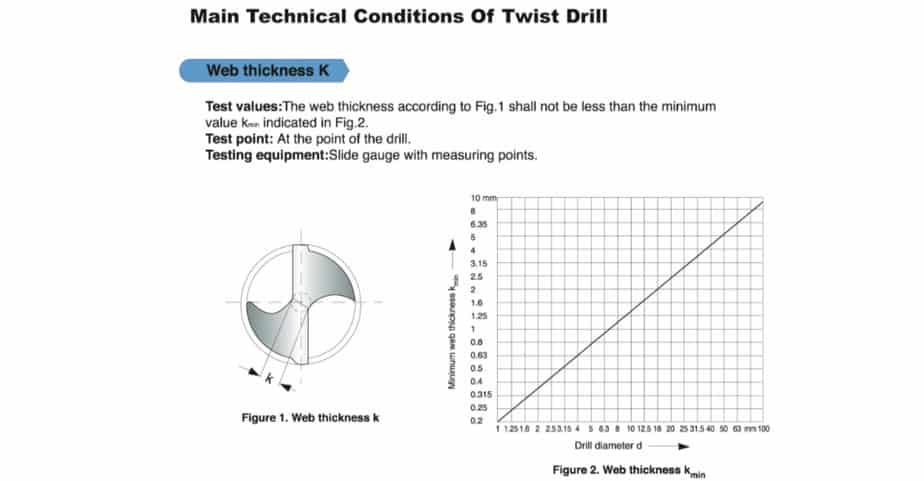

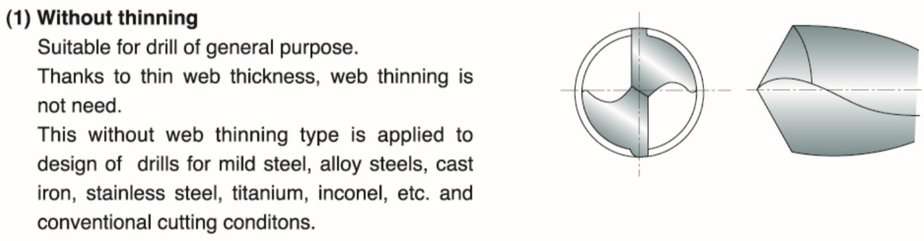

What is Web Thinning in Manufacture Twist Drill?

To understand web thinning, it’s imperative to know what the “web” in a drill is.

Basically, the web is the center part of the drill’s body; it’s what connects the lands to the body. Therefore, web thinning is the process or the procedure of reducing the center part of the drill.

You do web thinning to decrease the cutting resistance just at the edge of the chisel.

Different Results You Can Get With Web Thinning

As we know, you can decrease the thickness of a twist drill bit’s web.

Moreover, you can actually achieve four (4) different results if you perform web thinning.

Depending on what you’re looking for, you can perform:

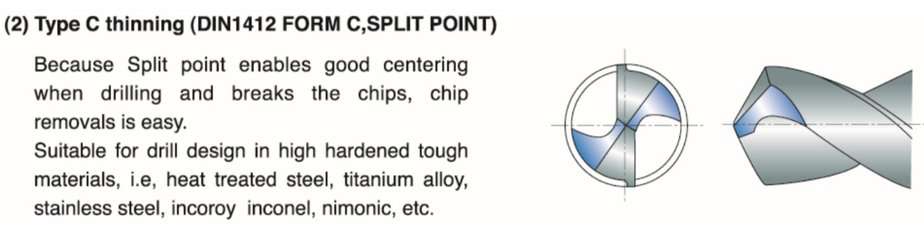

- Type C Thinning (Split Point)

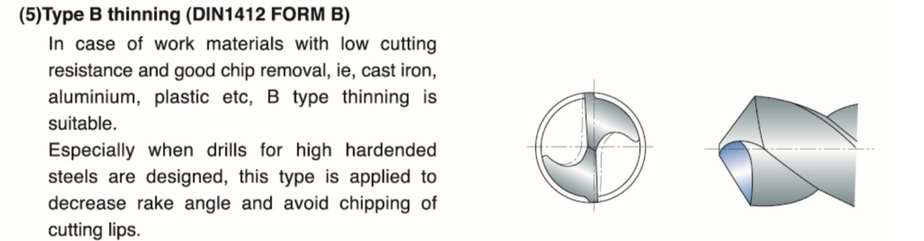

- Type B Thinning (Form B)

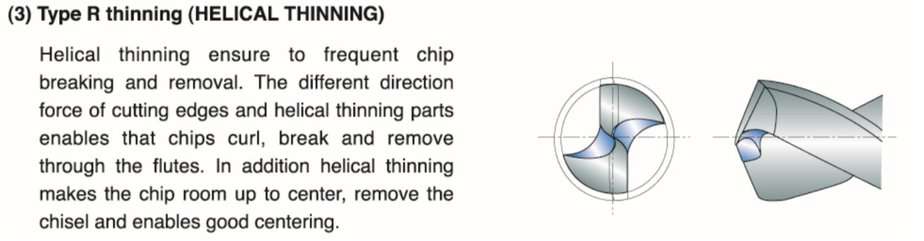

- Type R Thinning (Helical Thinning)

- Type A Thinning (Form A)

Type C Thinning is the most ideal if you’re going to be working on tough and hardened materials because of the split point.

Type B Thinning is perfect if you plan on working with materials that have low levels of cutting resistance. Furthermore, you’d want to perform Type B Thinning to avoid chipping of the cutting lips.

Type R Thinning or helical thinning would help you make sure that there’ll be chip breaking and removal frequently. Because of the different directions of cutting edges, it’ll easily help you with centering.

Last but most definitely not least is Form A or Type A Thinning. It’s considered the narrowest web in its final form. More so, it also offered wide fluted drills which ensure smooth and easy chip removal.

Titanium Twist Drill Bits vs. Cobalt Drill Bits: Which is Better?

From their composition alone, you already know how different they are.

To start off, they differ in terms of the principal material used to manufacture them. Titanium drill bits are usually made of steel. Cobalt drill bits are made from a combination of a kind of steel alloy and cobalt.

Titanium drill bits are coated with titanium carbonitride or titanium nitride; while cobalt bits are just coated with what they’re made from.

In terms of the material they’re capable of working on, cobalt drill bits work with harder and tougher materials better. Titanium drill bits, on the other hand, work perfectly with soft materials such as wood, plastics, soft metals, etc.

Unlike cobalt drill bits, titanium drill bits aren’t made from titanium as their core is steel – it’s just dubbed and called titanium drill bits because they’re coated with titanium.

How Do I Clean and Maintain My Twist Drill Bits?

A lot of twist drill bit manufacturers wouldn’t give these guidelines because all they want is for you to purchase from there.

But we here at Tenyu Tools Co., Ltd, we’ll teach you the proper way on how you can maintain the quality of your twist drill bits.

- Use a clean cloth and wipe your twist drill bits with it every time the work is done

- When needed, apply little amounts of machine oil after you clean them

- Store your drill bits independently; avoid mixing them with other elements so you can avoid oxidation, which leads to rusting

- NEVER use a twist drill bit for wood for metal – and vice versa; not only will it damage your drill bits, you also run the risk of breaking or damaging the material too

Which Supplier Makes the Best Quality Twist Drill Bits?

You can find many HSS drill bit manufacturers; especially now when the demand for it has gone up.

Here in China, no other twist drill bit supplier is banked on but us here at Tenyu Tools Co., Ltd. For over 15 years, we have provided a wide array of twist drill bits to over 990 clients from all across the globe.

We’ve proven the efficiency and the effectiveness of our products not only through the physicality of it, but also with the performance and the overall results they’ve had when they utilized it.

The Best Twist Drill Bit Manufacturer

Tenyu Tools Co., Ltd. wouldn’t be named as the best twist drill bit manufacturer if it weren’t for the excellent and the most relied on Research & Development (R&D) Team we have.

Without our team, our clients wouldn’t be able to order custom twist drill bits!

Because of our creativity, hard work, and our innovative feats, many businesses from different parts of the globe considered us as their go-to company for the manufacturing of their twist drill bits.

Is it Safe to Purchase Twist Drill From Tenyu Tools Co., Ltd?

Yes, Tenyu Tools Co., Ltd. is considered to be the top brand when it comes to twist drill bits.

Even if a lot of experts defer the fact that it’s not safe to purchase online, we here at Tenyu Tools have an online workshop where we showcase our products.

In addition to that, we can give you a free sample of what you’re requesting!

All you have to do is to send us an email! We’ll respond to your queries fast, plus, we can give you a free quotation of the orders you need!

What’s better is that the minimum order quantity (MoQ) that we require is just about 100 pcs! Purchasing more will get you discounts right off the bat!

Unlike how you can get it with other twist drill bit manufacturers, you don’t need to purchase thousands to get a discount!

Twist Drills Must Know The Knowledge Points

Twist drills are one of the most typical as well as most convenient method to place an opening in steel, wood or various other non-ferrous materials with a drill bit however with numerous alternatives to pick from it is necessary that you make use of the proper one for your details application. Doing so will certainly raise manufacturing, reduced operating expense and also give you with the precise surface you are trying to find.

Twist drills are rotating cutting devices that usually have 2 cutting edges and also 2 grooves which are grooves created in the body to offer reducing lips, to allow the elimination of chips and also to permit coolant or cutting liquid to get to the cutting activity. They are recognized by the:

- Shank style – Straight or Taper

- Length – Screw Machine, Jobber or Taper length

- Material

- Helix or Spiral of the flutes

The Twist Drills Of Right Material Can Make a World of a Difference

Selecting the correct layout for the application specifically in high quantity applications can be an expense conserving choice. Broadband steel is the basic objective tool and also fits numerous brief run and also upkeep work. Cobalt twist drills offer longer life and also can be performed at greater rates, while carbide drills are the option when problems of feed, rate as well as rigidness are maximum. Coatings can include life to every one of these tools,

Relied on Brand for Over a Century

Tenyu Tool of twist drill manufacturers a vast choice of typical twist drill bits for your benefit, and also if unique setups or customized drills are required we provide totally free quotes and also quick distribution. Our “NATIONAL” brand name of twist drills has actually been counted on making excellent quality tools for over 100 years, offering the demands of sectors such as:

Automotive

Aircraft

Fluid Power

Machine Shops

as well as More

To obtain the very best outcomes as well as device life from your drills make sure to review our 6 standard drilling concepts.

Our thorough understanding of using geometries, tool products, and also finishes to twist drills makes certain that we supply you with the most effective details in order to complete your preferred outcomes. Allow Regal Cutting Tools be your carrier for your spin drill as well as twist drill little bit requirements. See our big option listed below.

To obtain a far better suggestion concerning which twist drill BITS your company may require, review our post concerning applications by market.

Why Work With Tenyu Tools Co., Ltd. For Twist Drill?

Apart from the fact that we can manufacture custom made and original twist drill bits, you can also choose our pre-made twist drill bits!

We have 118, 130, and 135-degree point angle twist drill bits that vary in style, shape, and function!

Tenyu Tools Co., Ltd. is China’s top twist drill bit supplier because:

- We are ISO certified

- Wherever you are, our products are accepted and are permitted to be utilized

- We can manufacture many different types and kinds of twist drill bits

- You can get all of your orders in 2 to 3 weeks from the date of confirmation

Never overspend on the twist drill bits that you need with Tenyu Tools Co., Ltd! Get the best and the highest quality of twist drill bits for a reasonable and competitive rate!

Get yours now and never look anywhere else!