Cutting Tool Manufacturers

- Your preferred Cutting Tool Manufacturers in China

- Your Cutting Tool Manufacturer Expert,

- You can find one-stop solution from Tenyu Tools.

- We hold ful capabilities ranging to Manufacture Cutting Tool

- You can get the custom Cutting Tool Manufacturing

Tenyu Cutting Tools Manufacturers

Cutting tools, often used by machine part manufacturers globally have been in great demand lately. While there is an abundant number of them available in the market, you may find it hard to figure out which one you should buy. Tenyu Tools, China as your preferred cutting tool manufacturer, brings you a definitive guide that will help you get answers to the questions that might be crossing your mind.

- Manufacturing Machine for Diamond Cutting Tools

- Diamond Cutting Tools Using

Tenyu Tools’ diamond cutting tools will always be within your expectations. Whether you need a 1/4” shank, a 1/2 “ router shank, or any other size or kind of diamond cutter, we can help you!

Diamond Cutting Tools Supplier – The All-Inclusive FAQ Guide

A definitive guide to frequently asked questions on Cutting Tool Manufacturers

Who are the best cutting tool manufacturers in and around the Asian region?

Among a majority of cutting tools manufacturing companies in the market, it may get hard to choose the right one for yourself. To make your decision easier, shall we recommend Tenyu Tools, China.

Tenyu Tools is a proven cutting tools company in the Asian region. They have their client footprint in and around the region, who entrust them with their cutting tool requirements. If you are on a lookout for the best cutting tools, Tenyu Tools is your best bet.

What kind of products can cutting tools suppliers provide?

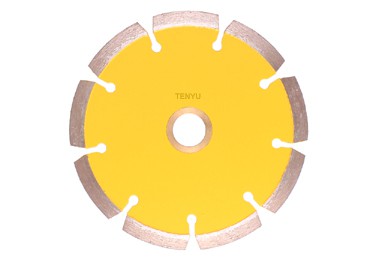

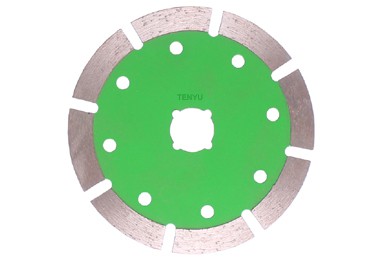

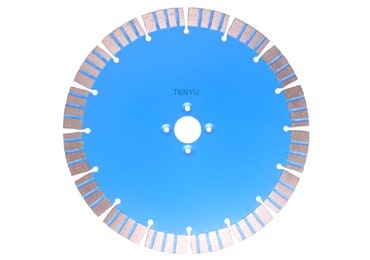

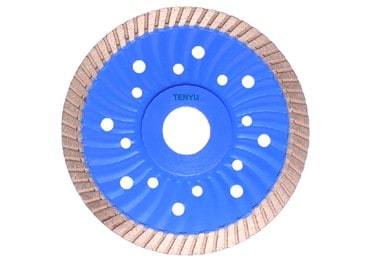

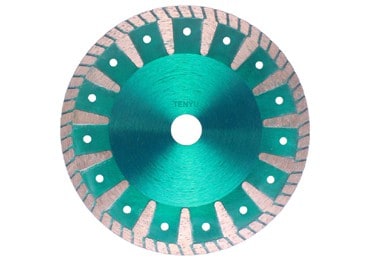

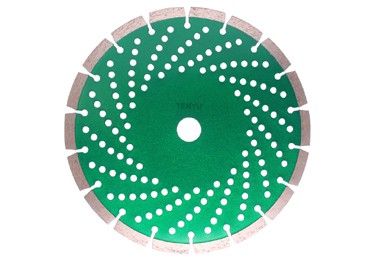

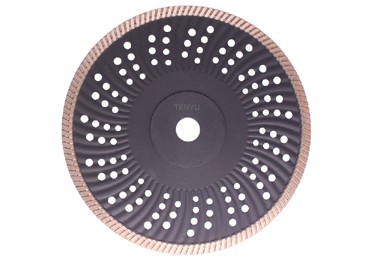

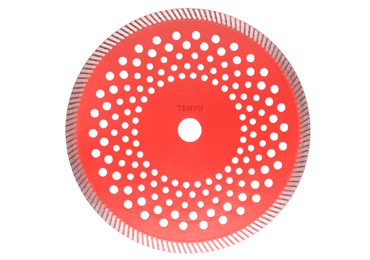

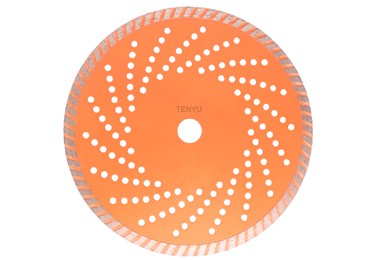

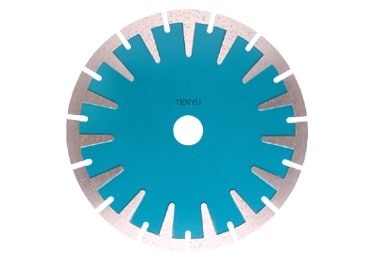

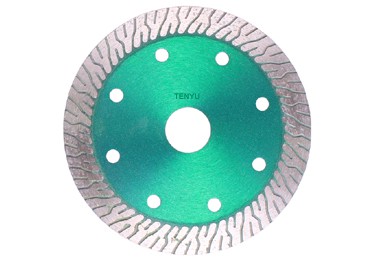

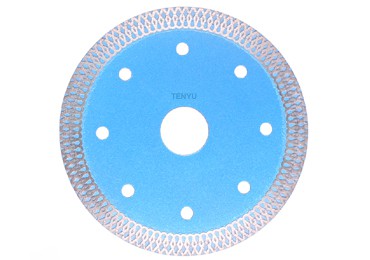

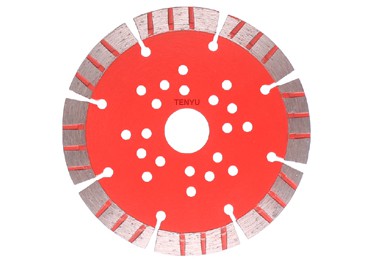

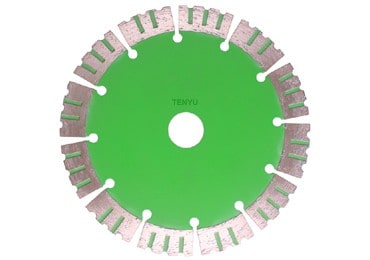

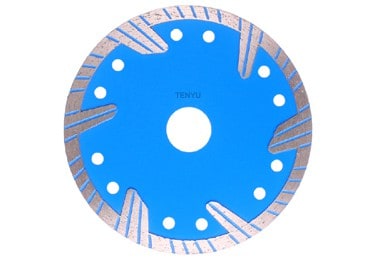

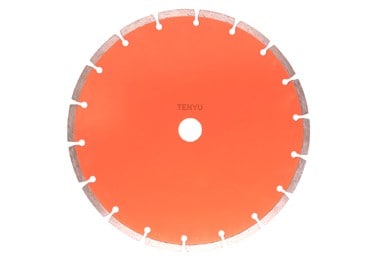

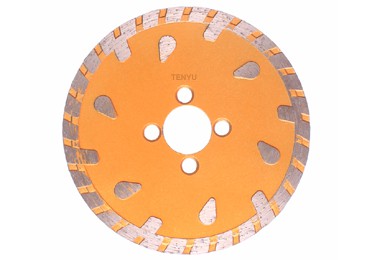

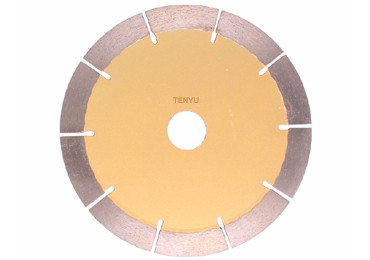

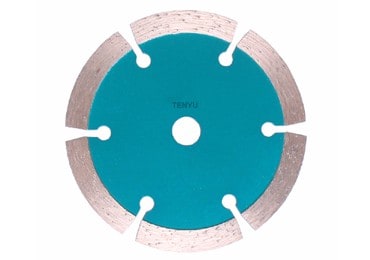

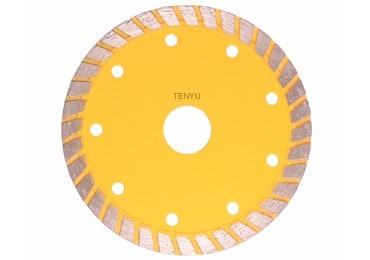

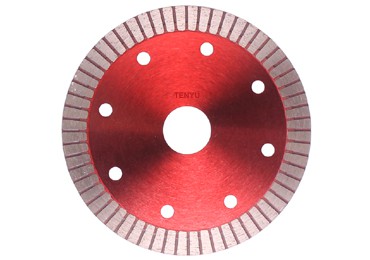

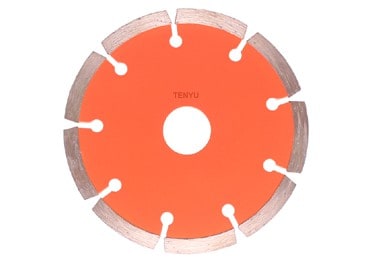

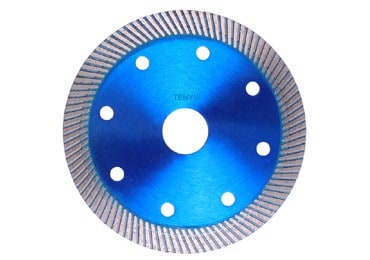

Cutting tool suppliers like Tenyu Tools deal in a range of cutting products like diamond saw blades, saw blades, hole saws, drill bits, grinding wheels and more. If you have any of these requirements you can always reach out to the sales team. To get the details, you can always visit the website www.tenyutool.com.

Tenyu Tools is indeed a reliable cutting tools company in the Asian region. They have a wide range of cutting tools on offer. Among their most popular range of cutting tools are the saw blades, drill bits, screw extractors, and more. If you are on a lookout for the most efficient yet affordable machine cutting tools, Tenyu Tools is your best bet.

What are cutting tools meant for?

In the area of manufacturing, cutting tools are often deployed to cut through materials. In general terms, these tools are used to create inserts and remove any excessive material from the surface to clear any deformities. Cutting tools are often pointy on one end and are used by mounting them on different machines.

Cutting tool suppliers often claim that the cutting tools have a higher hardness than the material they are meant to cut. Also, they can sustain higher temperatures generated by frictional resistance during the cutting operation.

Cutting tools manufacturers make a variety of cutting tools and classify them into the following types:

- Single Point Tools

- Multi-Point Tools

This classification is based upon the kind of contact the tool makes with the workpiece.

Single Point Tools

These tools have a single sharp cutting edge and are used to remove deformities or excess material from the surface. These tools are used for a turning operation, like ones you see on lathe machines. These tools work only on the external diameter of a workpiece. The cutting edge of the tool is usually round, and not very pointy, thus enabling it to withstand a greater force.

Multi-Point Tools

As the name suggests, these cutting tools can have more than one cutting edge and are used for a variety of cutting operations. These tools can be mounted on a machine and used by rotating it at high speeds on a fixed stand. These tools are commonly used in boring, drilling and mining operations.

Your reliable cutting tools company like Tenyu Tools manufacture both single as well as multi-point cutting tools for your use.

What are some properties to consider while selecting a cutting tool?

Cutting Tools are only as good as their material properties. These properties play a key role in defining the life and performance of these cutting tools. If you are planning to buy a new cutting tool, you will need to pay attention to them. Some important properties of cutting tools can be described as following:

- Wear Resistance

- Strength and Toughness

- Hot Hardness

- Young’s Modulus

- Tool Life

Wear Resistance

The ability of a tool to resist the wear that happens during operation is known as wear resistance. When the cutting tool comes in contact with the work-piece surface, frictional forces may cause it to wear. If you don’t have a tool capable enough to sustain this wearing force, it will break and may cause injury. Also, it will not produce the desired results.

Tenyu Tools as your preferred cutting tool manufacturer, adds Cobalt to the tool composition which increases its longevity and wear resistance.

Strength and Toughness

When a cutting tool moves on the work-piece surface, great amounts of pressure and temperatures are generated. If the tool is not capable or strong enough to withstand these forces, it may chip away or might even break. Maintaining just the right amount of composition when manufacturing a cutting tool will make the tools strong and tough enough. Cutting tool manufacturers like Tenyu Tools make sure to add Nickel or Molybdenum while manufacturing a cutting tool. This is the reason, our cutting tools are proven to work excellently under high pressure conditions and are chosen by clients like you from across the globe.

Hot Hardness

As discussed earlier, high temperatures can be generated due to the resistance produced by the cutting operation. The cutting operation produces heat which is capable of melting the tool and may also break it off. If your cutting tool cannot withstand high temperatures it can bend with the heat due to the high pressure.

Tenyu Tools and many other cutting tool suppliers provide cutting tools mixed with Tungsten, Aluminum, Vanadium and Molybdenum in their composition. These metals help by increasing the heat tendency of the cutting tools, which is required to be higher than what is going to be cut.

Young’s Modulus

This term may sound technical, but is the measure of the stiffness of the solid material. Stiffness should not be confused with the hardness, toughness and the strength of the material. The value of the Young’s Modulus can be calculated as the ratio of the tensile stress and engineering extensional strain. This strain is the value of strain in the elastic portion of the physical stress-strain curve.

The equation for calculating the Young’s Modulus is:

E = σ/ε = (F/A)/(ΔL/L0) = FL0 / AΔL

Where:

E is Young’s modulus, usually expressed in Pascal (Pa),

σ is the uniaxial stress,

ε is the strain,

F is the force of compression or tension,

A is the cross-sectional surface area or the cross-section perpendicular to the applied force,

Δ L is the change in length (negative under compression; positive when stretched),

L0 is the original length.

Cutting tools from Tenyu Tools generally have a higher Young’s Modulus value and perform well during cutting operations.

Tool Life

As understood, tool life is the actual duration from manufacturing upto the moment the tool wears out and is no longer fit for use. Life of a cutting tool can be determined using the Taylor Tool Life Equation, which is: v(T)n=C.

Here, “v” is the cutting speed in m/min,

“T” is the tool life, in minutes,

“C” is the cutting speed for a tool life of 1 minute,

and “n” is the Taylor component.

Cutting tools manufactured at Tenyu Tools have a significant life and perform well under rough cutting conditions.

These tool properties play a key role in selection of the most appropriate cutting tool from your preferred supplier like Tenyu Tools.

How are cutting tools classified according to their purpose?

Cutting tools manufacturing companies produce cutting tools for a variety of purposes including Boring, and Indexing. If you are looking for the same, here are some things you should know about:

Boring Cutting Tools

Cutting tools used for Boring are usually multi-point tools that work to enlarge a drill hole casted already. These types of tools work on the internal diameter of a cast hole thus increasing the same. This helps give it a smooth and clean finish thus making it ready for the next process.

Indexing Tools

These types of tools are specialized and are used to make the work-piece circularly indexed. Indexing involves a piece to be moved from one location to the other quickly yet precisely. The work-piece is held in an index tool just like you see in a metalworking lathe. These type of tools are commonly used on milling machines and many other drill tools.

What kind of tools are produced by cutting tool manufacturing companies?

Since there are a variety of tools manufactured by cutting tool manufacturers across the world, it completely depends upon the manufacturer and the supplier to decide what kind of tools are required. Where some companies may have a set menu of tool manufacturing practices, others can produce most to all of the tools known till today. If you are uncertain about what kind of tools to order from companies, you can contact their helplines or reach out to the supplier.

Tenyu Tools as a preferred cutting tool manufacturer and supplier, has a whole menu of cutting tools to cater to your business specific production and machining tools requirements.

Here are some cutting tools that we can manufacture easily using our advanced manufacturing methods:

- Boring Tools

- Indexing Tools

- Reamer Tools

- HSS spiral taps

- Roll taps

- Forming taps

- Spiral point taps

- Straight taps

- End mills

- Twist drills

- Hole Saw Core Bits

- Glass/ Metal Drill Bits and more.

Are cutting tools manufactured according to the material of construction?

Yes, cutting tool companies claim to manufacture cutting tools using their type of construction and material used for the same. There are several types of cutting tools and in order to have the best, it is important for you to have the best. Some of them have been discussed below:

Brazed Tip Tools

These tools are manufactured by joining two different materials using a third one. It must be noted as not to confuse Brazed Tools with Brazed Alloys. Brazing is done at higher temperatures as compared to Brazing Alloying. Brazed Tip Tools are a cheaper alternative to other specialized tools. Brazed tools are better as compared to standard ones when it comes to the wear resistance and toughness.

Carbon Steel

Though lower grade, these tools are hard, tough and acquire strength when hardened at a certain temperature. Carbon steel cutting tools are suitable for low temperature cutting operations. These tools are composed of cheap, easily available and forged carbon steel. At a hardness rating of 62Rc, these are generally used with wood cutting.

High-Speed Steel

HSS offer greater wear resistance and hot hardness values as compared to Carbon Steel because of its material composition. HSS made cutting tools can be used for metal cutting at speeds comparatively faster than carbon steel. Cutting tools made with HSS can cut through metal easily and don’t melt at high temperatures. They are suitable for interrupted metal cuts using different types of machines and processes.

Cast Alloys

Introduced in the 1900s, Cast Alloys have been in regular use. With a hardness value of 55-64Rc, cast alloy cutting tools offer better wear resistance values but lay slightly less on the toughness scale.

Cutting Tools made out of cast alloys can be used at higher speeds than HSS cutting tools. They retain their hardness at temperatures up to 800oC.

Carbide-made cutting tools

Carbide made cutting tools have a high hardness value and offer greater temperature stability. The high value of Young’s Modulus makes them the perfect choice for manufacturing cutting tools. Carbides are usually made up of Tungsten and Carbon, mixed well in a proportion of 94:6 weight by weight. After mixing them, they are sintered with Cobalt at a high temperature thus making them tough for cutting operations.

Tenyu Tools has a wide range of Tungsten Carbide cutting tools which last for longer durations and perform well under rough temperature and pressure working conditions.

Ceramics

These cutting tools are made by sintering Boron Nitride and Aluminum Oxide at 1700oC. Ceramics are refractory in nature and can withstand temperatures of up to 1200oC. Ceramic cutting tools are expensive to produce, thus are reserved for high-quality machinery only.

Tenyu Tools can help you with your Ceramic cutting tool requirements.

What precautions must be taken when handling cutting tools?

Cutting tools can be both helpful and hazardous at the same time. If you are using cutting tools regularly, make sure you take maximum and appropriate precautions.

Following is the information mentioning the hazards and precautions that can be taken while using cutting tools.

Hazard #1:

Improper use and inappropriate cutting conditions may cause tool breakage and expulsion, thus posing a risk of injury.

Precautions:

Use safety guards and goggles.

Refer to the user manual and notes.

Use the tools only under recommended cutting conditions.

Hazard #2:

Impact load or a rapid increase in cutting resistance due to abnormal/ irregular or excessive wear may cause tool breakage and expulsion, thus posing a risk of injury.

Precautions:

Change faulty/blunt tools to avoid excessive wear.

Use safety guards and goggles.

Hazard #3:

The cutting tool and the workpiece may become extremely hot during cutting. Touching them with bare hands may result in burns.

Expelled hot chips, sparks, and heat generation also pose a risk of injuries, burns and even fire.

Precautions:

Wear gloves, goggles and safety guards.

Make sure the machine is stopped and tools like cutting nippers and clippers are used.

Make sure you have a fire prevention solution in place.

Hazard #4:

Using poorly balanced chuck and tools at high revolutions may cause tool breakage and in turn injuries.

Precautions:

Wear gloves, goggles and safety guards.

Check for any vibrations and abnormalities during the chuck revolution.

Contact Tenyu Tools for further support!

If you have any more questions that you would like answered about cutting tools and cutting tool manufacturing companies, we suggest you reach out to our team at our designated helpline numbers or leave us your query in the email inbox.