Diamond Saw Blades

- Why Choose Tenyu As Your Wholesale Diamond Saw Blades Manufacturer?

- Your Finest Trustworthy Diamond Saw Blades Suppliers -Tenyu Devices Deal Industrial High Quality

- You can obtain constant top quality of the Diamond Saw Blades.

- You are accepting the very best Diamond Saw Blades in China,

- Tenyu Tools can supply any kind of optimum orders for your company.

- You will certainly not see any kind of flaws on our Diamond Saw Blades.

- You can obtain our skilled Diamond Saw Blades modern technology.

- Send your query to custom-made your Diamond Saw Blades currently.

Reasons why your competitors import diamond saw blades from Tenyu Tools China

Have you ever fell short of the demand for diamond saw blades from your clients?

Or have seen a decline in the sale of your construction/manufacturing products?

While you ponder over the question of why is it happening, why not have a look over the reasons why your competitors are buying diamond saw blades from Tenyu Tools, China?

There are plenty of reasons why retailers/ wholesalers/ importers buy diamond saw blades from us. Some of them being:

- High-performance Diamond Matrix

- Use of premium synthetic diamonds

- Faster cut rate with a constant depth

- Enhanced material removal capabilities

- Customized Arbor for all cutting applications

- Thinner kerf to increase the cutting speed

- 200 times more life than conventional abrasives

- Wide-masonry applications including concrete and marble

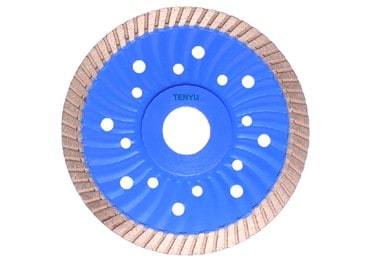

- Zero chips continuous Turbo-Rim

And much more.

- Applications Diamond Saw Blades from China

- Diamond Saw Blades Factory from China

Wholesale Diamond Saw Blades – The Complete FAQ Guide

Diamond Saw Blades for every purpose

Granite Marble and Tiles

Concrete and Masonry

Dry and Wet Cutting

Whatever your requirements may be, we at Tenyu Tools, China, have a solution!

Our large inventory caters to every need of yours. The range of Diamond Saw Blades that we provide is enterprise-grade with specifications suiting different materials and applications. Select from a full range of diamond saw blades, the one that suits your needs the most.

There are two main categories of Saw Blades that we provide to importers, wholesalers, and retailers like you!

Saw Blades

Wood Cutter Circular Saw Blades

Sizes available from 4 inches 30 teeth up to 14 inches 140 teeth.

Aluminum Cutting Blades

Circular saw blades for cutting aluminum metal.

Grass Cutting Blades

6T Steel razors weed eater lawn mover blade and Carbide tip brush grass cutter blade.

Mini Circular Saw Blades

Circular saw blades for small-scale applications.

Diamond Saw Blades

High-quality diamond cutter continuous rim saw blades for heavy applications.

Before selecting a product, it is important to know how it is made and works. Gaining this knowledge will let you ensure a great working experience.

How do we manufacture our diamond saw blades?

Two main components make up a diamond saw blade- the steel core and the segments.

Steel Core

The steel core of a blade is a flat metal disc used to support the outer blade segments. The outer shell of the blade contains diamonds that help with making clean cuts.

(a) Vacuum Brazed/ Sintered Attachments

Lower cost, higher volume blades use vacuum brazing or sintering processes to make attachments. These blades are intended to be used for dry cutting on low horsepower equipment. Cores used on these blades are constructed using simple manufacturing methods for more aggressive applications.

(b) LASER Welded Attachments

Being an advanced method to attach cores to the outer segments, it results in making the strongest bonds of all. Excelling at LASER welding, we at Tenyu Tools continue to develop and innovate laser welding techniques to deliver the toughest of the diamond saw blades. Steel cores that we use for our blades are thicker, heat-treated, precision ground, and come with high tensile strength as well. This allows them to be used in both dry and wet cutting applications and make deeper cuts. Also, these blades experience comparatively less drag when subjected to high rpm.

Segment

Blade segments constitute the cutting part of the blade and are made up of two components, namely diamond, and metal.

(a) Diamond Crystals

The diamonds that we use in our diamond saw blades are synthetic and not real. Though everyone knows that Diamond is the hardest substance ever known to us, but using a real one wouldn’t be cost-effective and will raise the manufacturing costs. This is the reason why manufactured diamonds or synthetic diamonds are preferred over real ones. Not only does it becomes easy to mold the shape, structure, set the size and strength according to individual requirements, but also saves costs linked to the construction process. It becomes easier when you can control the main features of the cutting diamond, to predict the cutting speed and blade life and work to improve the same.

Furthermore, we can also control the number of diamonds per square inch in the segment.

I. Number of Diamonds in our blades

The diamond saw blades that we manufacture, are suitable for both low and high horsepower saws. We manufacture blades with suitable diamond concentration per sq inch of the saw blade, so can be used for wide applications and cutting requirements.

II. Diamond Quality

We at Tenyu Tools, make use of high-strength and tough synthetic diamonds that resist heat and get sharper with every cut. The use of such high-quality diamonds helps in increasing the life of the blade.

III. Diamond Size

The last thing to consider, but not least, we take care of the size of the diamond so you don’t have to change your blade often. Best Quality diamonds are used to build the blades for hard substances like quartz while coarse size ones are used for soft materials like Asphalt and red clay bricks.

(b) Bonding System

Bonds in a blade are a mixture of metal powder that are used in a combination to achieve specific wear rates. Effective bonds help the diamonds to be held in one place, so they can be used for longer periods.

The blades that we manufacture have wear rates which is the capability of a metal to endure the result of abrasion. Metals that have low abrasion resistance such as bronze are soft and are used to make soft bonds. Hard bonds, on the other hand, contain hard metals such as Tungsten Carbide and are used to cut very soft abrasive materials like asphalt and freshly poured concrete.

How do our Diamond Saw Blades work?

Diamond saw blades are not used to cut materials, instead, they grind the metal or material surface using the exposed diamond crystals. The metal matrix that we use for our blades holds the diamonds in their place. Trailing behind each diamond shown is a bond tail that helps support the diamond.

As the blade is cutting the material, the exposed surface of the diamonds grinds the material resulting in cuts to be formed.

As the diamonds in the first layer of the blade metal matrix wear away, those in the second layer of the blade appear on the surface, thus carrying out a controlled erosion rate.

This cycle of erosion and layer exposure continues until all the diamonds on the metal bond section are eroded.

Once the cutting section is consumed, the blade will no longer grind, indicating that you now need a new blade for carrying out further machining operations.

Calling all importers/wholesalers to fill their inventories with the right product- the best diamond saw blade

Diamond Saw Blades from Tenyu Tools are the best when it comes to performance. At Tenyu Tools, you’ll get a multitude of blade options at an affordable price range. But how do you select the best for your inventory? How do you determine which blade will have the most demand from your customers?

To answer these questions, it’s important that you first understand how these blades work. Understanding the working of a blade will help you make the best choice with the right characteristics and cutting quality.

Look out for the quality of these four basic components:

- The metal core

- The synthetic diamond crystals

- The blade matrix

- The weld quality

The metal core is made of a steel disk that contains segmented rims to hold the diamonds together. These diamond crystals have sharp cutting teeth and can easily slice through hard workpieces.

The welds are connections that hold together the cutting segments to the core.

It is important to check and verify the quality of these components so you only sell the best. The quality of the diamond saw blades that we manufacture and supply is top-notch and uncompromised.

The quality of diamonds that we use helps cut the work surface easily. As the diamond’s upper layer on the top surface wears out, the matrix begins to reveal the embedded diamond crystals. Important is to consider the hardness of the blade as it determines how long the blade will actually last.

The basic rule that applies here is:

A blade with hard diamond bonds should be used for cutting soft and hard surfaces, so the diamonds are fully used before the matrix fades away completely. In materials like green concrete that are soft and the material is loose, if the blade bonds are weak or loose, the cutting diamonds will lose their grip and wear away easily without being fully utilized. Therefore, always consider the hardness of the blade.

Selecting the right product

For your cutting blade to last longer, your customers need to match the blade with the material as closely as possible It is important to consider the compressive strength, size, and hardness of the aggregate and the type of material used.

We at Tenyu Tools, manufacture blades with a compressive strength of 3000psi for soft materials and more than 6000psi for use on hard materials. We make available diamond saw blades that are suited for a wide range of applications.

It is thus prudent for you as well, to consider hard bond blades to use on lower-strength concrete and soft bond blades for use on high-psi value concrete. Similarly, hard aggregates such as trap rock, basalt, and quartz dull diamond particles quickly, therefore, it is wise to work with a soft bond blade so new diamonds can reveal on an as-needed basis.

The type of material used in the work material influence the performance of the blade. When you are cutting a material that has the larger size of ¾ inch and more, the blade cuts and wears slowly, however, coarse material of sizes smaller than ⅜ inch makes the blade wear quickly. The hardness of work will depend on what type of material is being used.

If you are working on surfaces like concrete, determining the sharpness of the sand is also important. Crushed or sand on the river bank is shard compared to the river sand that is round in shape which makes it less abrasive. The harder bond will be required depending on the hardness of sand.

It is recommended that you choose a blade based on the type of material you will be using., if you are using different types of material. Diamond saw blades are such that they can be used for a large range of work materials.

Another thing that is important for you to understand is the timing of making the cuts. If you are using the saw blade for concrete, you will have the option of cutting the control joints while it is still green or after it is hardened.

Often constructors prefer using the blades to make cuts when the material is still raw as it lowers down the percentage of random cracks and permits shallow joint depths of an inch or less. This is due to the sand present in the mixture which hasn’t bonded to the mortar and acts as an abrasive.

(Diamond saw blades from Tenyu Tools can be used to cut concrete, marble, tiles, stone, stone, building materials, etc., and more such surfaces.

Diamond Saw Blades are suitable for both Wet Cutting and Dry Cutting purposes!

Whatever your cutting preferences and requirements may be, we have a solution to meet every need of yours. If you are considering Dry Cutting, it would eliminate your chances to have the wet slurry and you have to cover your saw with water tanks and hoses. On the other hand, if you are looking to use a wet blade, it will reduce dust, but you will need to clear the slurry time and again. For indoor jobs, where you need to keep the work area dry always, A dry-cutting blade will be your only option, when you are working indoors and you need to keep the area dry.

When you order from Tenyu Tools, you get a complete range of diamond saw blades that are compatible with your every need.

Understanding the difference between Dry Blades and Wet Blades

The main difference between dry and wet blades is the type of weld.

Dry Cutting blades have segment welds and provide great help resisting so you don’t have to use water for cooling. These blades are intended for intermittent cutting and use on hand-held, low-horsepower saws. They can be the best choice if you are looking to make clean, crisp, and decorative patterned lines on concrete. These cuts are typically only 1/16 to ¼ inch deep.

Wet Cutting blades are used in walk-behind saws for cutting joints in cured concrete flat-work as water cooling allows for deeper cuts to be made.

Although you can use dry-cutting blades with water, wet-cutting blades cannot be used as dry-cutting ones as they require constant cooling and may break at higher temperatures to cause serious injuries.

Tenyu Tools, therefore, recommends using complete safety gear when working with sharp machine tools.

Get the most in performance and the best in cost!

Tenyu Tools, China, manufactures high-quality diamond saw blades that perform for the longest durations and come as among the most affordable in the market, thus giving you the maximum return and value on your investment.

This is one of the reasons why importers, wholesalers, and resellers prefer buying products from us at Tenyu Tools, China.

The diamond content in our blades makes the difference when it comes to abrasion and cutting capabilities. Moving from a standard blade to a premium one may raise your expenses by 20% or more, but the quality that you’ll get will be unparalleled and help you deliver quality-finished jobs for considerably long durations.

High-quality diamond saw blades for every purpose!

If you are looking to achieve the quality of a decorative hand-tooled joint without all the labor, you might feel the need of using beveled diamond saw blades with special cutting edges to produce chamfered or radial cuts.

Diamond Saw Blades for your cutting needs

Diamond saw blades consist of diamond-like coarse crystals on the cutting edges that help cut through concrete, tile, marble, and just about any work surface.

The amount, concentration, and the size of the diamond crystals determine the quality of the blade.

Diamond crystals here, do not refer to real diamonds, but synthetic diamonds that are much precise at the task. When manufacturing them, attention is usually paid to the three parts of the diamond- the amount, the concentration, and the size. These three factors will affect the quality and useful life of your diamond saw blade.

If the diamond grit is finer, the cutting result will be smoother. On the contrary, when the diamond grit is rough, the cutting will give a rough finish.

The diamond grit size affects the cutting speed as well. Rough diamond grits are suitable for concrete, and masonry purposes. Fine diamond grits are more suitable for tiles, glass, and other such brittle material.

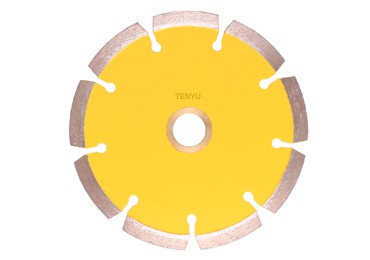

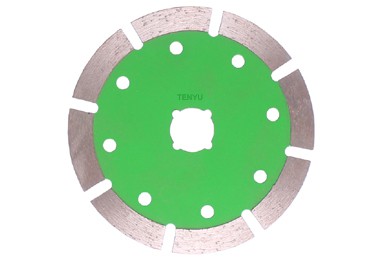

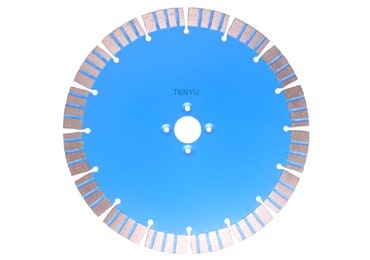

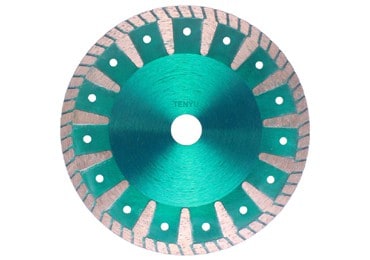

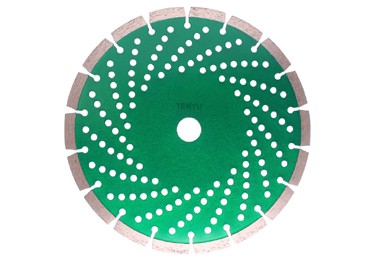

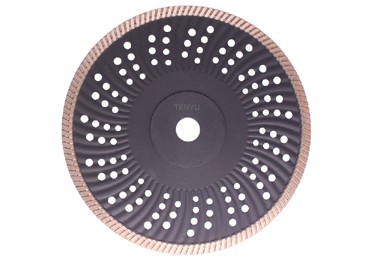

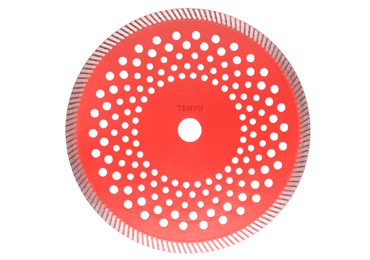

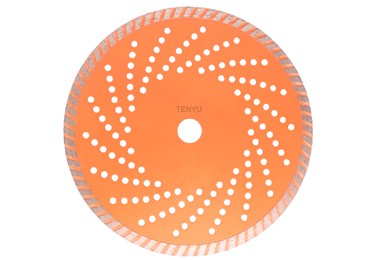

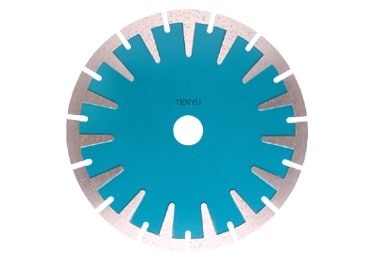

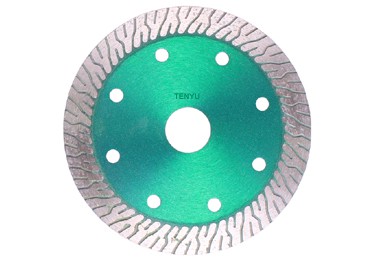

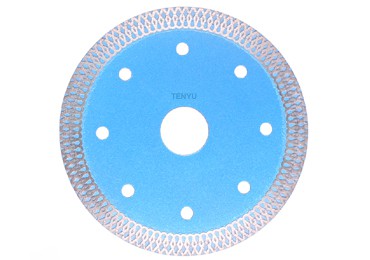

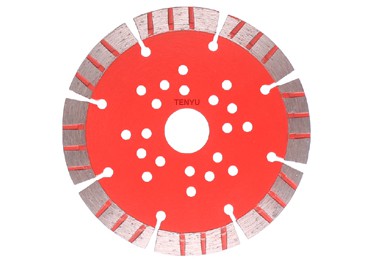

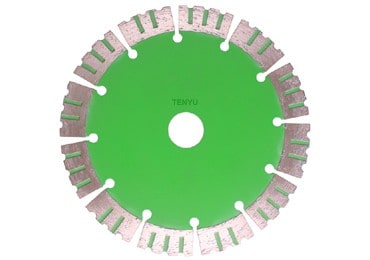

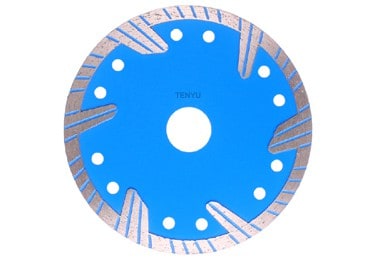

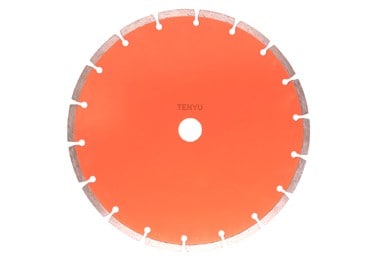

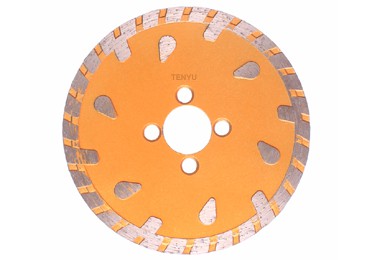

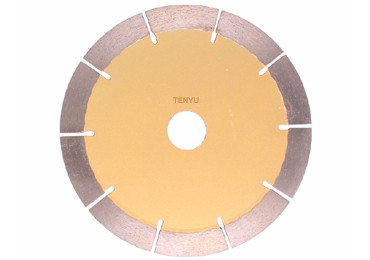

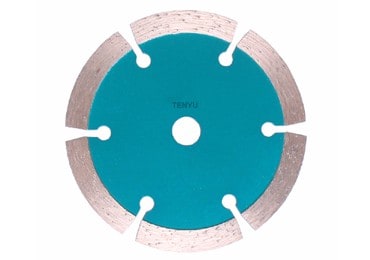

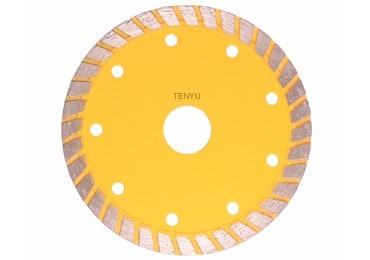

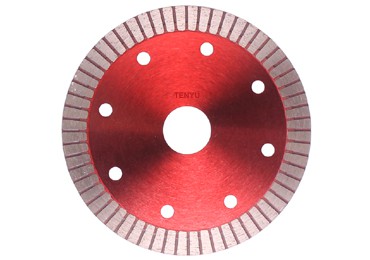

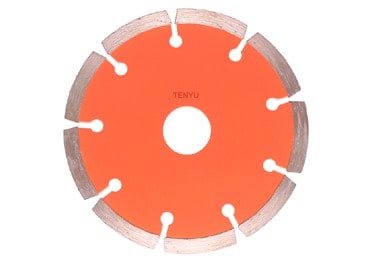

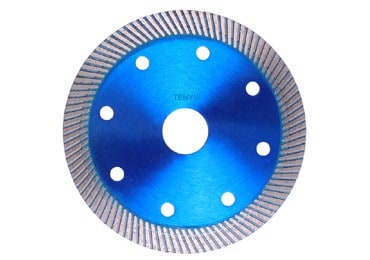

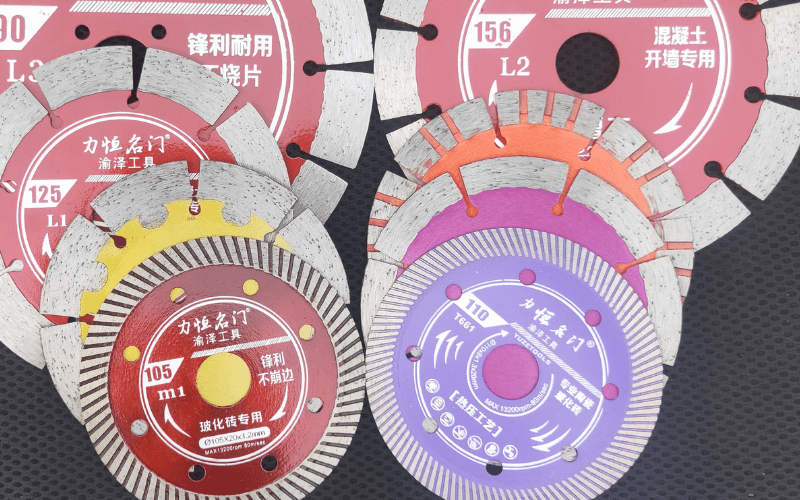

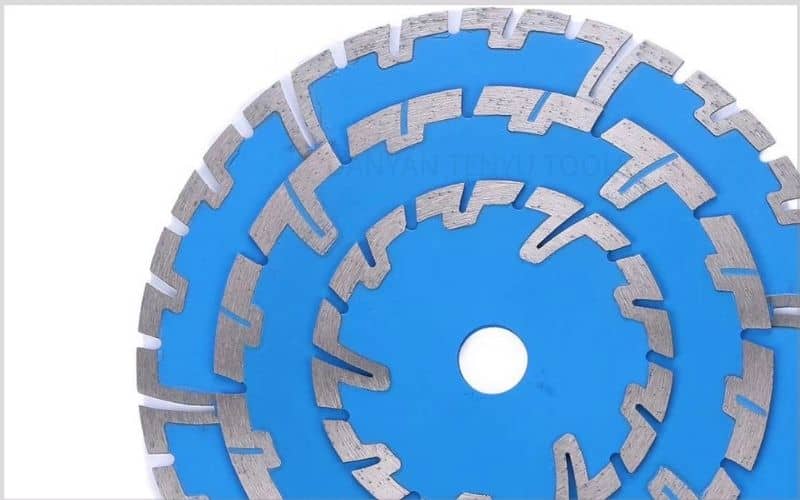

The diamond cutter blades can be divided into four types

- Continuous Rim Saw Blades

- Segmented Saw Blades

- Turbo Saw Blades

- Turbo Wave Saw Blades

It is therefore suggested that you get the size and the type of diamond saw blade which meets your needs.

You need to consider some things like the work surface, and the speed when you are looking to have smooth surface finishes on the material you need to cut. Selecting the right diamond saw blade to cut the workpiece will help extend the life of your saw blade.

We at Tenyu Tools provide you with different sizes of blades such as:

54.8mm – 400mm

400mm – 1200mm (LASER welded)

Now, take an example of a cutting tile.

Tiles are brittle materials that break easily if you are not careful enough. You can follow these steps when you are handling these materials:

- Use a marker on the tile to highlight the areas so it is easier for you to cut with a diamond saw blade. You can also use a wax pencil for this purpose.

- Place the tile on a flat and clean surface.

- Remember to cut the tile from the top. If you find that the blade is deflecting, stop cutting, and shift the tile slightly to start cutting again.

- As per the type of diamond saw blade, you are using, make sure you are providing adequate cooling during its operation.

- Do not press on the tiles forcibly. This prevents any chances of tile damage.

- Remember to use a low-speed cutter on tiles that are brittle and chip off easily.

- Lastly, no matter what you are cutting, always wear goggles and masks to prevent yourself and others.

Some additional tips and tricks when using a diamond saw blades

Extend the blade life, and carry out the toughest of the jobs effortlessly

Before starting with using the diamond saw blades for machining operations, make sure you check the correct direction of rotation. Always make sure to install the blade according to the direction of rotation.

- Fix a blade after you have successfully analyzed the same.

- Low-speed rotation speeds ensure user safety and are most recommended for use.

- Cutting while exerting less pressure on the machine will help extend the life of your blade as it prevents the blade from shearing forces.

- If you are using the blade for an extended period, make sure to check and inspect the blade condition at regular intervals. The sharpness of the edge may get deteriorated over time. You can sharpen the same using a blade grinder wheel.

- Always be careful when using blades for dry or wet cutting. As mentioned, dry cutting blades can be used for wet cutting purposes, but wet cutting blades cannot be employed at sites where you are looking to have a dry cutting in place. This not only helps with preventing blade deformation but also mitigates the risk of workplace fires due to heat from high friction.

- Make sure you consider different rotation speed for different work materials like tiles, natural stone, or marble. Also, check if the work surface is clean as it affects the cutting efficiency and cleanliness of the cut.

- The choice of blades also depends upon the hardness of the material to be cut. There may be chances that your blade bounces off the surface of the work-piece, so you would need to use a blade suitable with that particular surface.

Tenyu Tools China has got a diamond saw blade for your every requirement. Just make sure to keep your requirements clear.

Professional care and high maintenance is the key to better and productive use of your diamond saw blades. If you are looking to minimize your idle times with diamond saw blades that last longer, nothing is better than the ones manufactured at our factory in Tenyu Tools, China.

Get exceptional quality blades that are second to none.

No matter, you are a supplier, wholesaler, or retailer, or importer, we at Tenyu Tools have got a solution to your every need. All you need to do is reach out to us and we can give you the best advice to select the best for yourself and your customers.

Additional Content Diamond Saw Blade Manufacturers

Finding the best diamond saw blade manufacturer is key to your business’s success. Whether you’re involved in the saw blade industry itself, or if you’re just at retailing, merchandising, or distributing, working with the best diamond saw blade manufacturer could get you the success you’ve always been looking for.

But, do have a complete understanding of what diamond saw blades are?

Is a Diamond Saw Blade Used to Cut Diamonds?

The most common misconception people have with diamond saw blades is that they’re the tools that you can use to cut and slice diamonds. But, they’re not actually built for that.

You know them as diamond saw blades because the blades have fixated diamonds on the edge, which are used for the cutting or the slicing of hard, tough, and other abrasive materials.

You can use diamond saw blades to cut a wide variety of materials – from wood, plastics, stone, concrete, even steel, and metal.

Can You Use a Diamond Saw Blade to Cut Wood?

Yes, in fact, cutting wood is one of the primary uses of diamond saw blades.

You can cut any type of wood, from regular softwood, hardwood, maple, oak, cedar – or any other type of wood!

The benefit of trusting diamond saw blade manufacturers for your wood projects is that you can expect smooth, flawless, and high-quality cuts, thanks to the addition of synthetic diamonds on the edges.

In addition to that, you’ll be able to achieve results faster, quicker, and more urgently.

Are There Diamond Saw Blades for Stone and Concrete?

Yes, diamond saw blade suppliers manufacture specific sets of blades for cutting masonry. In fact, this is the main and the primary material you can use it for.

Take note, though – using regular diamond saw blades for wood to cut and slice through stone and concrete will not be effective. It can even, break your blades!

So, before you work on a project that involves cutting stone, concrete, tiles, or any other form of masonry, check if it’s the right and the correct type of diamond saw blade.

Where Do You Use Diamond Saw Blades?

While its flexibility and versatility allow it to be used in various industries and sectors, the most common use of diamond saw blades would be in the cutting of masonry such as stone, concrete, asphalt, cement, etc.

However, many diamonds saw blade manufacturers are designing it to be multifunctional to the extent that you’ll be able to use it in other applications too such as woodworking, metalworking, cutting PVCs and plastics, and many more!

Carbide vs. Diamond Saw Blades

A lot of people find it hard and challenging to choose between tungsten carbide-tipped (TCT) saw blades and diamond saw blades for their application.

While both of them bring certain benefits and advantages, you use them in different scenarios and environments. To start, let us discuss what each of them is.

Carbide-tipped saw blades obviously saw blades that are embedded with carbide at its tips or edges. Diamond saw blades, on the other hand, are those that have polycrystalline diamonds or PCD diamonds that help with the cutting.

Applications and Uses

The most ideal use of carbide-tipped saw blades would be in cutting both ferrous and non-ferrous materials such as steel and metal.

However, some woodworking techniques employ the usage of carbide-tipped saw blades too for more accurate, more precise, and faster cuts.

The structural and construction industry considers carbide saw blades to be their go-to or their primary option.

Diamond saw blades, on the other hand, are ideal for cutting concrete, stone, asphalt, and other forms of masonry.

Since diamonds are known to be the strongest stones in the world, you can count on them to help you with cutting the hardest and the most tensile materials.

Longevity

Some sources claim that diamond saw blades can last anywhere up to 12 – even 18 hours of non-stop cutting. Basically, if you use it for just 5 to 10 minutes a day, you can expect it to last up to a year, given the fact that you care for and maintain it properly.

Carbide-tipped saw blades, on the other hand, can last up to 12 hours only if they’re of the highest quality of blades and are maintained properly.

Since you’d use them for cutting non-ferrous and ferrous metals, they’re the most susceptible to overheating.

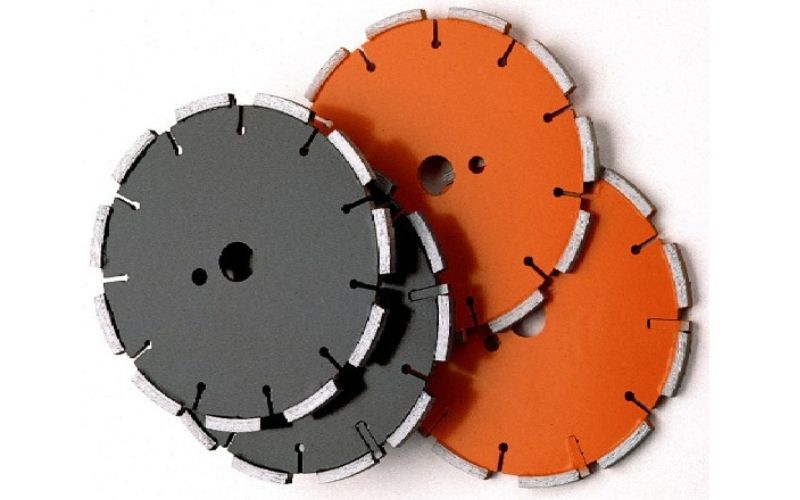

Physicality and Appearance

While the diamonds used by diamond saw blade supplier aren’t real diamonds, it’s still far from what carbide looks like.

Carbide usually made up of tungsten and carbide, is usually greyish-black in color. You can find them on carbide-tipped blades and saws.

Diamond-tipped saw blades, on the other hand, appear in a different color. They’re often shiny and grained=.

As a matter of fact, some diamond saw blade manufacturers use diamond bits color-coding to distinguish the use or the application of the diamond saw blade – whether they’re for stone, masonry, or concrete; for wood; for metals and steels; and so on.

Those are the ways on how you can distinguish carbide saw blades and diamond saw blades.

Is Choosing a Good Diamond Saw Blade Supplier Important?

Just like in any other type of business, choosing the diamond saw blade manufacturer to work with is imperative.

No matter how well your business is going, and no matter how long you’ve been in the industry, you MUST always be on the hunt for the best and for the most reliable diamond saw blade manufacturing company.

It’s not like purchasing a single diamond saw blade – we’re talking about thousands, to hundreds of thousands of diamond saw blades manufactured and produced for you. Imagine if the program for creating these blades will have an error – it’ll affect the whole and the entire line of production.

How Do You Choose the Best Diamond Saw Blade Supplier?

Now, let’s get to the fun part – and that is choosing which diamond saw blade manufacturer you should work with.

If you thought that choosing one is easy, think again! There’s nothing more challenging and more hassle than the act of choosing which diamond saw blade manufacturer to trust for your business.

Luckily, we have compiled some of the best procedures on how you can choose the best diamond blade suppliers in the market.

Check Their Experience

Experience will always be the best teacher – and that is what the case is in choosing a diamond saw blade manufacturer.

Choosing a wholesale diamond blade supplier with little-to-no experience can actually do more harm than good.

So, part of the first things you want to check would be a supplier’s experience.

How Does Their Factory Look?

Checking the diamond saw blade factory of a particular manufacturer can help you have a better understanding of how they do their business.

Are they clean and organized? Do they have everything in check or intact? Or do they care less about their factory?

Though not all the time, checking the diamond saw blade factory of a manufacturer can help you distinguish early whether or not they’re the manufacturer you should work with. Imagine yourself walking down the aisles – would you be interested to work with them?

Do They Have Recurring Clients?

Many people consider client acquisition and client retention to be two (2) of the things that dictate how well businesses perform.

And, as a matter of fact, that’s true most of the time! Diamond saw blade wholesalers that are trustworthy and are reliable would have clients who would work with them consistently – and it’s because they enjoy the quality of service that their manufacturers and their suppliers provide!

What are Their Capacities?

In choosing, you need to ask the following questions:

- Are they capable of producing or manufacturing the specific products you need?

- Do they have the capacity of producing what your minimum required production capacity is?

- Can they abide by the supplies your business requires?

You may be able to find wholesale diamond saw blade manufacturers that can produce quality saw blades at the best rates but are you sure that they’re up to the challenge of strictly being within what your required amounts are?

Check Portfolio and Website Reviews

The next best thing you want to do is to check the reviews left by clients and customers. Depending on the type of business they have would be the review they’ll leave.

So, for instance, you might see a combination of moods – from other comments being happy with the delivery, the mode of payment, the response times, while others could be talking about how good and how high-quality the products are.

NOTE: Take note, though of the reviews you’ll read. Some of them might be fake and just written to up and to improve the image and credibility of the manufacturer, so beware.

Can You Trust Chinese Diamond Saw Blade Manufacturers?

There are tons of options in the market for wholesale diamond saw blade suppliers.

You can purchase from American companies, European companies, Japanese companies, English companies, etc.

Yes, Chinese diamond saw blade wholesalers are trustworthy and are reliable. As a matter of fact, we’re considered as the best and the most practical choice for diamond saw blades!

Wherever you are in the world, you can easily choose to work with a Chinese diamond saw blade manufacturing company to supply you with high-quality diamond saw blades! We can guarantee that it’ll be the cheapest, the most valuable, and the most impacting choice you’ll ever make!

Why Choose Chinese Manufacturers of Diamond Saw Blades?

Choosing a Chinese wholesale diamond saw blade supplier can actually bring a lot of benefits not only to your company or your business but also to some of your processes, too!

In fact, we’ve listed and gathered some of the best reasons why you should choose a Chinese diamond saw blade manufacturing company for your orders of wholesale diamond saw blades.

Higher and Better Profitability

The first and possibly the most sought-after reason is that you’ll be able to have higher profitability.

Most Chinese wholesale diamond saw blade suppliers don’t compete with rates any longer, since they often travel on the same boat. This is the reason why they improve and develop the quality of their products instead – at the same rates and prices!

Access to Wider Product Ranges

Another advantage you can get from working with a Chinese diamond saw blade supplier is that you will be able to have access to larger and farther ranges of products.

The Chinese are known to be the initiators in the industry – they’re not afraid to start something new and something untouched in the market.

What this simply means is that you have the chance to get better and newer products than your competitors!

With these reasons alone, you’re already set if you’re looking to work with a good quality diamond saw blade wholesaler!

How Do You Import Wholesale Diamond Saw Blades From China?

Importing from China is not as complex and as complicated as many of you might think. In fact, it’s just as easy as how you would order from a local diamond saw blade manufacturer – it just involves too few other steps.

The only additional things you need to perform in ordering or importing diamond saw blades wholesale from China are:

Step 1: Identifying Import Rights

The very first step in importing diamond saw blades from a Chinese manufacturing company is to identify the import rights that your country has.

Different countries have different import rights, so there is no specific set of rights to follow.

Step 2: Knowing the Exact Goods and Products to Import

After you know and figure out the importing rights of your country, the next step is to determine the products and goods you’re looking to purchase and import.

You need to determine every aspect of the product – from the type, the dimensions, the make, etc.

NOTE: You would need this for the declaration or the packing list document you will use when you officially go with the importation.

Step 3: Find a Supplier

The next step is to find the diamond saw blade manufacturer you’ll be working with. You can follow the basic guide in finding the diamond saw blade supplier we’ve detailed above.

Step 4: Finding the Freight and Cargo Transport

Lastly, you’d have to find the cargo and the freight transport company that will deliver your goods!

That’s how easy and simple it is to order and to import diamond saw blades from China to whatever country you are in!

NOTE: This is a general procedure. There might be some that are and aren’t included, based on how you think of ordering or importing.

So, you can choose to follow this structure or have a different one based on this.

Which Chinese Diamond Saw Blade Wholesale Manufacturer Should You Trust?

Herewith us at Tenyu Tools Co., Ltd., we will never fail you –we’ve been the most trusted wholesale diamond saw blade manufacturer in China and we’re still the best until today!

Whether you need custom diamond saw blades for concrete, for wood, for steel or metal – even for plastic, we’re just a call away!

We are considered to be the best and the top Chinese diamond saw blade wholesaler not only because of the quality of our work but also because of the response times and the client experience that we offer all our customers.

- You can get custom diamond saw blades from the best diamond saw blade wholesaler in China

- You can get a free quotation or a free estimate of the diamond saw blades you need!

- Your orders will arrive within 2 to 3 weeks max from the date and time of confirmation

- All your concerns and queries will be answered!

Work With China’s Top Wholesale Diamond Saw Blade Manufacturer

Are you a wholesaler or a manufacturer of diamond saw blades and you’re looking for a company you can trust? Have you ever tried finding the diamond saw blade supplier that you know you can bank on from the production quality, production capacity, to the rates and prices?

If so, then the best choice you have is none other than us here at Tenyu Tools, Co., Ltd! For more than a decade and counting, we’ve been specializing in the diamond saw blade manufacturing business, providing high-quality products to businesses and companies from all around the world.

Being the most sought-after Chinese diamond saw blade supplier, you can never go wrong in choosing us!

It’s time for you to choose to work with the best and the most trusted diamond saw blade wholesale manufacturer – work with us and never worry or think about where to get the best quality of diamond saw blades ever again!

It’s time to leverage the capabilities of our products to increase your profits and outshine your competitors in the market.

Be a leading supplier of the top-grade diamond saw blades in the world, contact our Sales Team now.