What Are the Different Saw Blade Teeth Types?

If you examine different design saw blades closely, you will see differences in how the blade’s teeth are arranged as well as their tooth patterns. This article will explain what they’re named as well as what sort of reducing they’re often used for, allowing you to choose the best choice for your work. With any hope, you’ll be able to save yourself a lot of time and headaches. Alternate Top Bevel (ATB), Flat Top Grind (FTG), and Triple Chip Grind are the three most common tooth styles (TCG). Both slim kerf and full kerf blades are available with these tooth types.

Saw Blade Teeth from the ATB Family: ATB, HiATB, ATBR, and ATAF

ATB stands for Alternate Top Bevel.

The normal ATB is a functional work with a bevel from the top, exterior portion of the tooth pitched down to the blade’s reverse. The bevel series alternates between one tooth pitched from the left and one from the right. This sequence goes all the way around the blade. The angle of the tooth’s bevel is generally between 10 and 20 degrees. A 20-level bevel will almost probably provide a cleaner cut than a 10-level bevel. However, it lowers more slowly and generates considerably more warmth when rubbed. Cross cuts are ideally suited to ATB blades, especially those with a high tooth matter. ATB blades finish cuts neatly and smoothly. They can be used for hole cuts against the grain, although the results aren’t great. ATB blades are also good choices for basic objective blades with a medium tooth matter.

HiATB (High Alternate Top Bevel) / HATB (High Alternate Top Bevel) / Hi-ATB (High Alternate Top Bevel) / Hi/ATB (High Alternate Top Bevel)

The HiATB blade differs from the ATB blade in that it has a bevel of 25 levels or more. HiATB teeth also cause far less tearout than conventional tooth types. It is optimized to provide the cleanest, most finished cuts possible. Utilize the HiATB for reducing easily changeable goods such as laminates, melamines, veneers, and plywood. They’re also great for making ultra-fine cuts in wood. The Hi-ATB blade has a significantly shorter life-span than other blades because to the high, sharp edges, although they will still survive a decent amount of time if used by low-volume professionals or for home project DIYers. If your saw blade is starting to dull, here’s a quick guide to help you. out.

Alternate Top Bevel with Raker / Alternate Top Alternate Face with Raker (ATBR, ATB/R, ATAFR)

The ATBR is the last saw blade in the ATB design. It is also known as ATAFR, however it is most commonly referred to as ATBR. It usually has a five-toothed replicating pattern. The first four teeth are ATB, whereas the fifth tooth is a flat-top raker. After it decreases, the level leading raker tooth leaves a level surface area. It features a large craw in between each 5 teeth series to efficiently remove sawdust. For crosscuts, the ATBR is optimized. On both soft and harder woods, it leaves a neat finished cut. Consider it an outstanding well-rounded basic target tooth pattern that also works moderately decently on split cuts.

Alternate Top Alternate Face (ATAF) is an acronym for Alternate Top Alternate Face.

The ATAF is a modified version of the ATBR that lacks a final raker tooth. The ATAF grinds both the top and the face of the table at an angle. When these two grinds come together, you get a sharper cut with a much sharper side. The ATAF is ideal for decreasing breakable product while also providing smooth, extra outstanding cuts.

Saw Blade Teeth Types That Aren't ATB

FTG stands for Flat Top Grind.

FTG saw blades are designed to rip wood down the grain. They’ve been improved to get rid of product chips and sawdust from the teeth quickly and effectively. The FTG blade provides quick, precise cuts and is both sturdy and long-lasting. One downside to consider is that it will almost likely chip and cause substantial tearout on almost all cuts. Keep this in mind when using it on woods and other materials where appearance is important. The FTG is also the only tooth pattern that leaves a perfectly flat foundation while grinding. As a result, it’s ideal for minimizing splines and grooves.

Triple Chip Grind / California Triple Chip Grind (TCG / CTCG / C/TCG)

A trapezoid-shaped leading tooth is followed by a level raker tooth that sits somewhat decreased in the TCG configuration. This design is repeated all the way around the blade. TCG blades combine a well-balanced lowering pressure with less tooth drag and complementary chip circulation. Because of these characteristics, the TCG is one of the more durable blades. The TCG tooth design produces very low chip out and tearout while reducing weak goods. This makes it an excellent choice for chipboard (OSB), non-ferrous and ferrous steels, plastics, MDF, laminates, and very woods. A California TCG-CTCG is also available. It’s a one-of-a-kind blade with a very specific purpose. It’s a specialist miter saw blade that’s used to make ultra-fine cuts in picture windows, buildings, and doors, among other things.

Take a look at our recommendations for selecting the right saw blade. Here’s a rundown of some safety and security tips to keep you from injuring yourself when using a table saw.

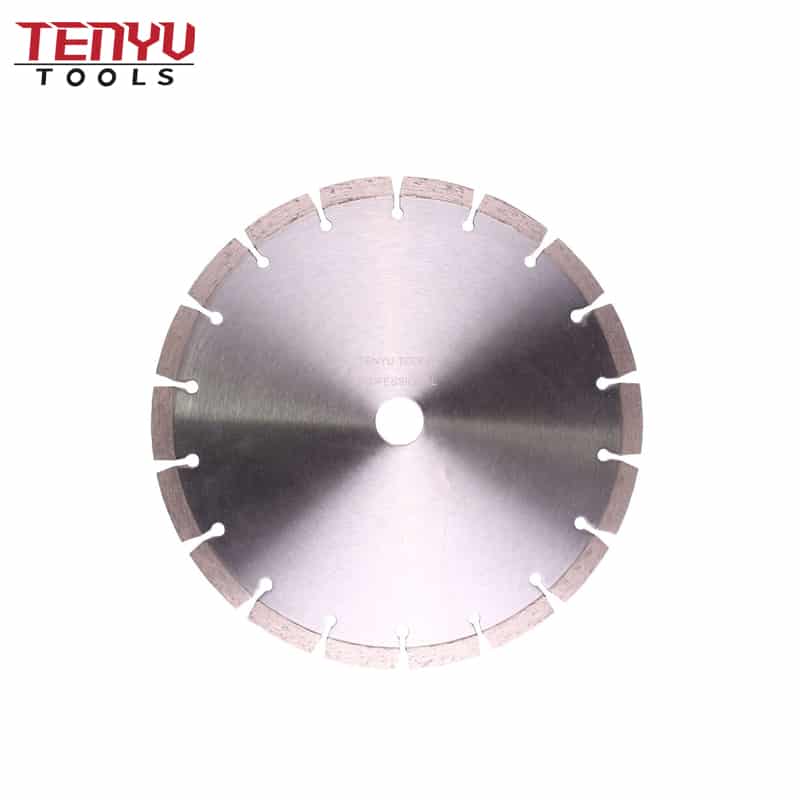

- The Concrete Saw Blade is the ideal tool for quick and precise cuts in marble, engineered stone, and masonry.

- The small cutting gap and less chipping are additional advantages of our blade. It can be used both wet and dry, making it incredibly versatile.

- The flange is designed for easy mounting on the saw.

- The ATB (Alternating Top Bevel) offset tooth design helps to prevent chipping and splintering while also providing a smooth cut.

- The tungsten carbide teeth provide excellent wear and heat resistance, making the Wood Saw Blade an ideal choice for woodcutting projects.

- With a size of 4 inches, this TCT Circular saw blade is designed as a general crosscut blade that can be used on a variety of materials, including softwoods, hardwoods, plywoods, chipboards, panel boards, MDFs, and more.

- The durable Titanium Carbide tips provide razor-sharp cuts and long life, while theNon-Stick coating reduces friction to protect against rust and resin build-up.

- Large YG8 carbide teeth are precision-ground with fine-grit diamond wheels so each tooth planes the Aluminum for an exceptionally smooth finish.

- With a MAX RPM of up to 5,000, this heavy-duty production blade features increased thickness of kerf and plate for fast and smooth cutting action.

- This circular saw blade is made of high-quality tungsten carbide for a long life and superior performance.

- The expansion slots and stabilizer vents reduce noise and vibration, while the sharp teeth and non-stick anti-rust coating help extend the life of the blade.

- It can be used for ripping wood, crosscuts wood, plywood, and laminate – making it the versatile solution for all your needs.

- Whether you’re Dry cut or wet cut, our blades are designed to give you a smooth, clean cut every time.

- With improved efficiency and exceptional performance, our Concrete Saw Blade will provide you with fast, smooth cutting in a variety of materials.

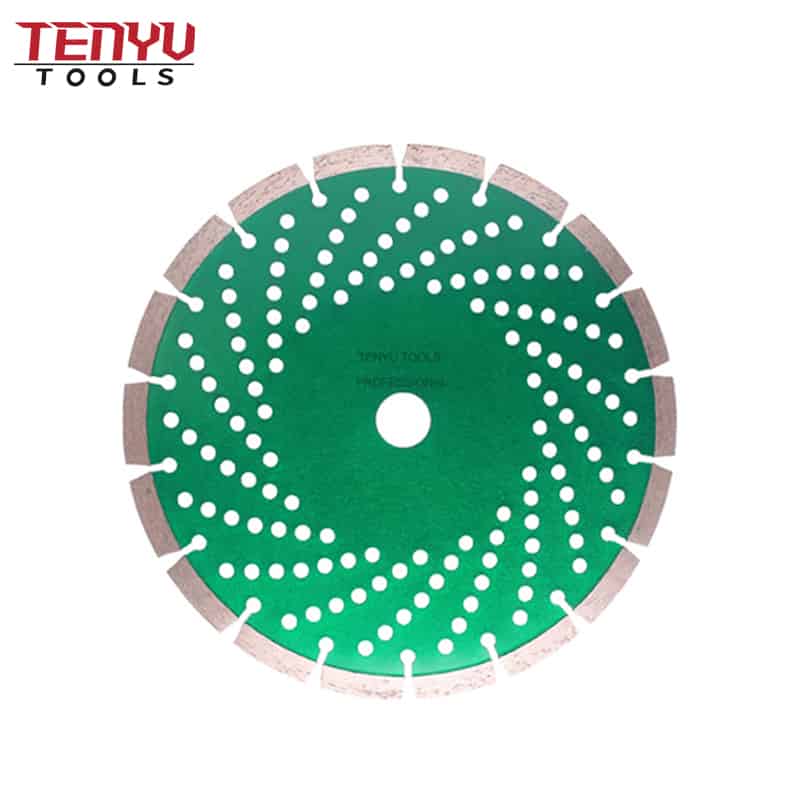

- And they can be used for both dry and wet cutting! Perfect for cutting granite, tile, brick, marble, ceramic, and more.

- with their high diamond content, these blades are designed for fast stock removal and better cooling – delivering super clean and fast cutting results with excellent life.

- The Brick Cutting Saw Blade is designed with high quality diamonds grit that provides up to 4x longer life.

- The segment slot design reduces vibration for a smoother cut and the cooling holes extend the service life of the blade by keeping it cooler during use,making it ideal for both dry and wet cutting.

- With a consistent diamond content and even distribution, this disc provides smooth cutting in most concrete and masonry materials.

- Suitable for Granite, quartzite, and hard stone cutting, the general-purpose blade is tough enough to tackle any project.

- Excellent blade life and cutting speed, the Ceramic Tile Cutting Disc is an excellent value for any job.

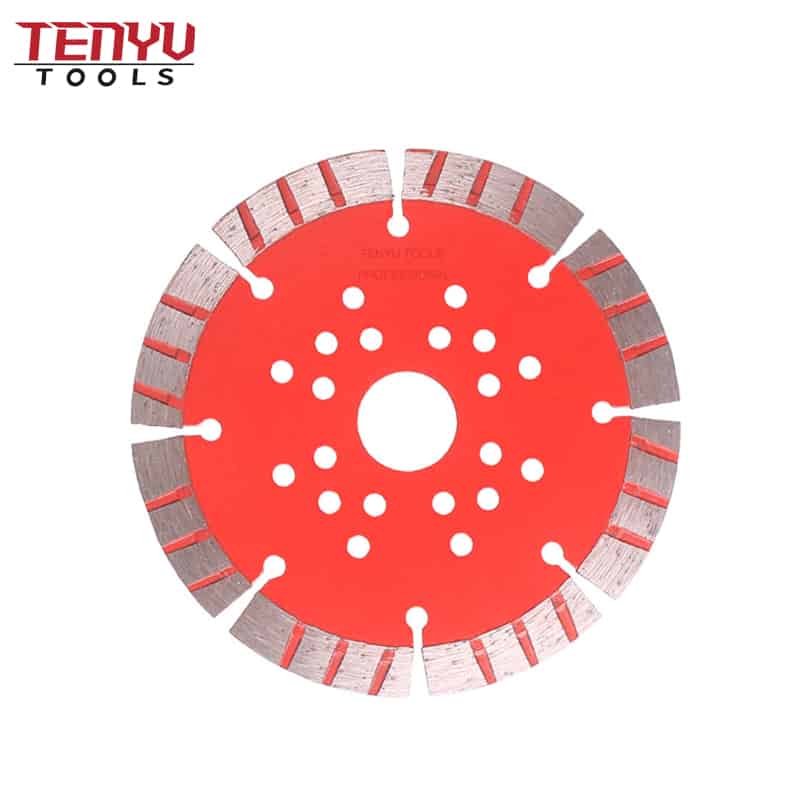

- Featuring a special vented hole to keep the blade cool during use, hot-pressed diamond turbo teeth for smoother and faster cuts, and slant protection teeth for added safety.

- They’re perfect for both wet and dry cutting, and are highly efficient for deep cuts

- slant protection teeth for added safety.

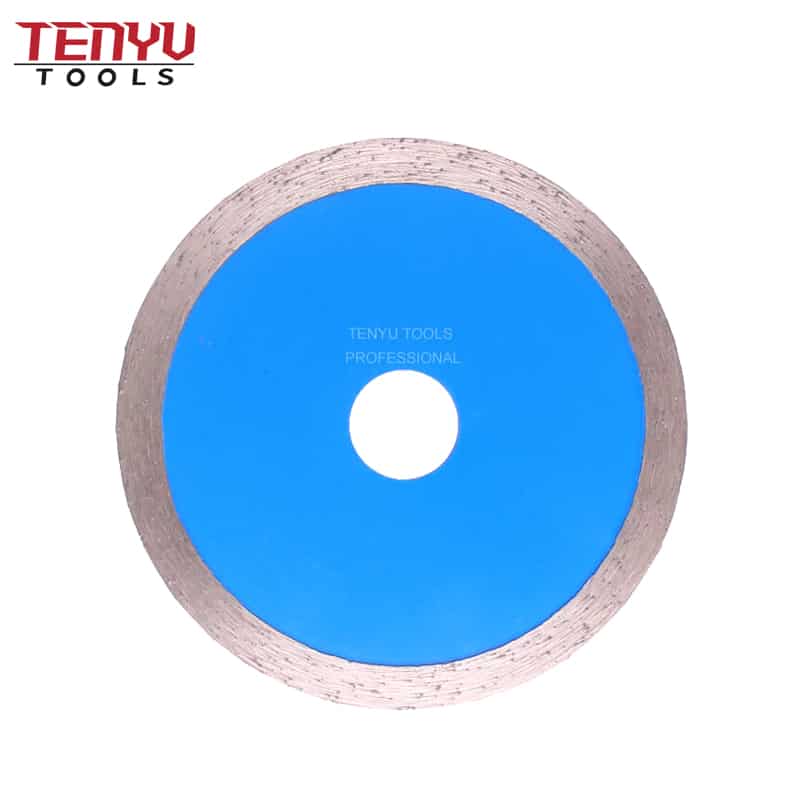

- The Wet Saw Blade is designed for ceramic tiles and porcelain. It is only suitable for wet cutting to prevent the cutting edge from being damaged.

- The blade is designed for stable performance and smooth cutting, without any chipping or damage to the tile.

- The blade produces very little noise while in use, making it perfect for use in sensitive areas.

The numerous saw blade teeth are shown here. Aside from the CTCG, there are a variety of other specialty tooth creations available. However, the blades listed below are the most common ones you’ll come across outside of a dedicated woodshop.