Granite Cutting Blades

- Tenyu Granite Cutting Blades

- You’ll have the ability to accomplish smoother cuts utilizing our Granite Cutting Blades

- All our Granite Cutting Blades live 5 times longer than various other suppliers’

- You can define or make your very own Granite Cutting Blades

- You can pick from wet-cutting as well as completely dry Granite Cutting Blades.

- You can obtain Tenyu Tools’ Granite Cutting Blades wholesale, any place you might be!

- High diamond concentration embedded into each of our Granite Cutting Blades

- Developed with the operators in mind, we’ve made safety and security as well as effectiveness our leading concerns.

Tenyu Tools- A trusted Granite Cutting Blade Manufacturer!

If you are in the mining or manufacturing sector, you know how important it is to have solutions that cater to your numerous requirements. And when it comes to having quality material cutting requirements, you need a partner who provides the best quality cutting blades in the market. For your every need, you can trust Tenyu Tools as the best granite cutting blade manufacturer.

Granite Cutting Blades- The Entymology!

Granite Cutting Blade is another name for Diamond Saw Blades. They are named after the purpose that they serve. Since diamond grit coated blades are heavily used for cutting through hard materials like granite, marble, concrete, and more, they were given the name Granite Cutting Blades.

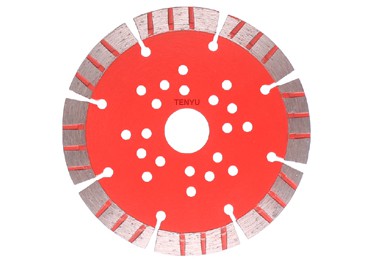

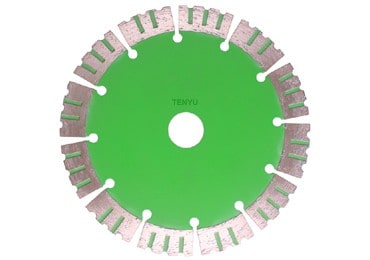

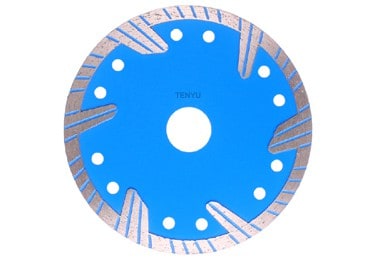

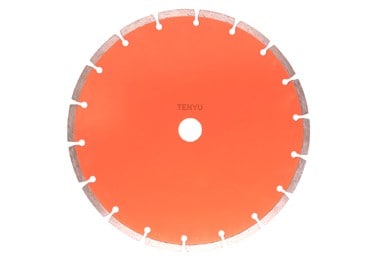

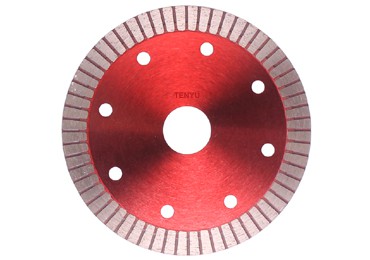

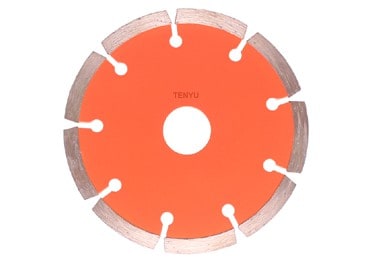

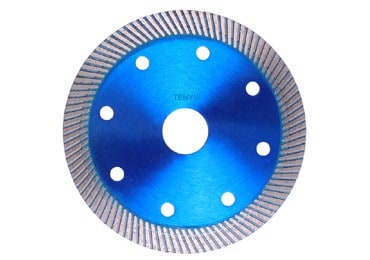

Types of Granite Cutting blades

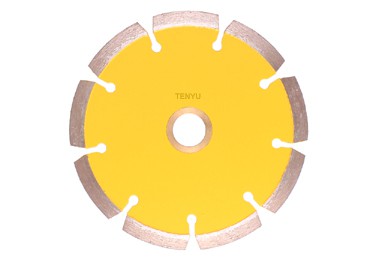

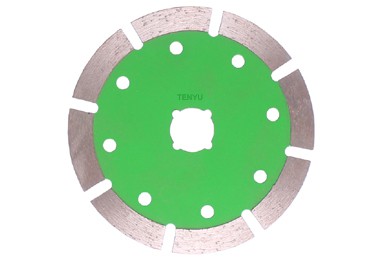

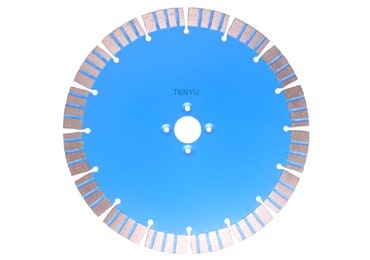

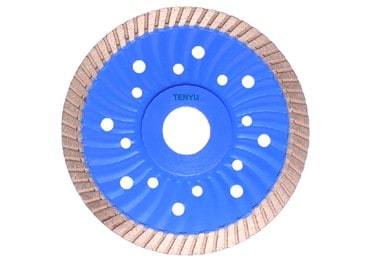

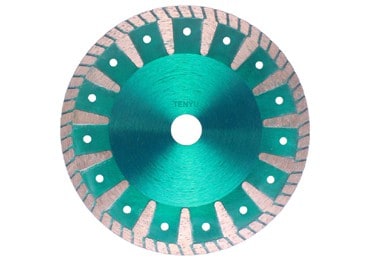

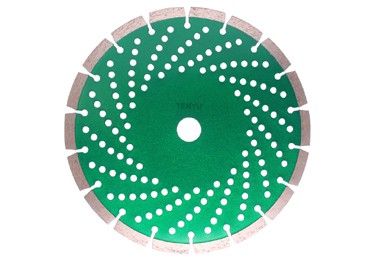

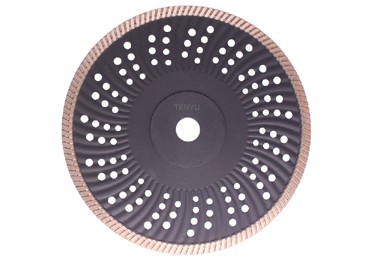

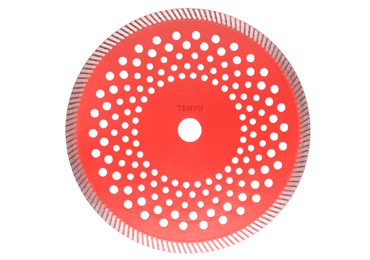

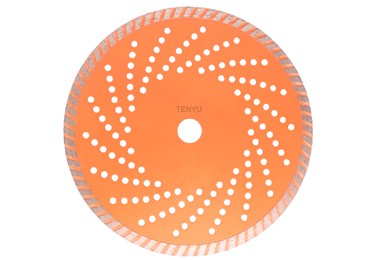

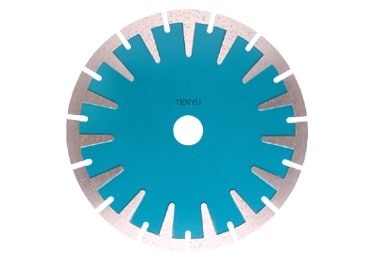

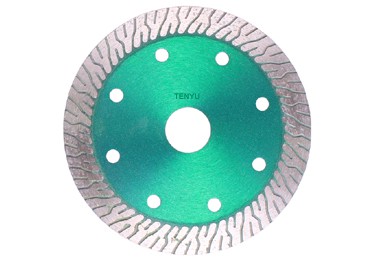

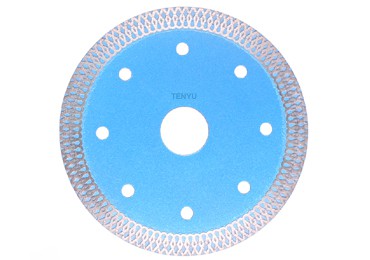

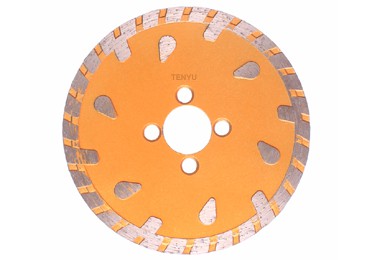

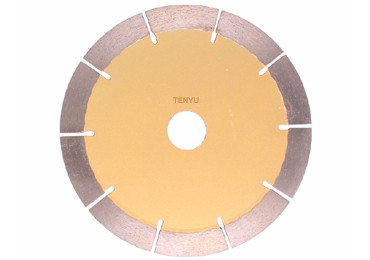

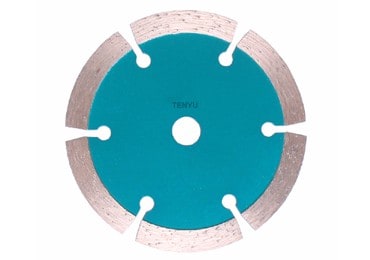

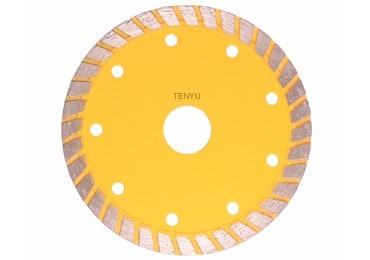

Granite Cutting Blades or as better known as the same Diamond Saw Blades are available in different shapes. These can be:

- Circular Diamond Saw Blade

A circular-shaped cutting blade with sharp, abrasive diamond grits attached to the periphery.

- Diamond Gang Saw Blade

A long steel plate with diamond grits welded on to the surface.

- Diamond Band Saw Blade

A closed flexible steel band with diamond grits electroplated to the surface.

There are multiple ways in which a granite cutting blade can be manufactured. These processes can be classified into three types:

- Electroplating

- Vacuum Brazing

- Sintering

Electroplating

The process of electroplating allows granite cutting blade manufacturers to produce a thinner blade. Thickness is an important factor when you are looking to cut granite without chipping the stone. If your blade is thin, it will give you cleaner cuts without wasting excess material.

Thin blades can be helpful in achieving precision cuts.

The process of forming thin granite cutting blades is done by using an electric current to fuse diamonds onto the metal surface. This affixes them onto the metal surface and provides the metal a durable and precise cutting angle.

Vacuum Brazing

The process of vacuum brazing involves welding diamonds to the surface of the granite cutting blade. This way, diamonds can be attached to the outer surface which results in a fast cutting speed i.e. ideal for cutting hard materials like granite. Since blades manufactured using vacuum brazing are not thin, they produce rough cuts and may also produce chipping. In order to get precise and clean cuts, you might prefer using electroplated blades.

Sintering

One of the most common types of granite cutting blade is the sintered blades. They are manufactured using a steel base of the blade which is covered in micro-sized diamond segments. These segments are fused to the blade using heat and pressure. This process of sintering does not melt the metal, rather just fuses the diamonds to the steel base using intense pressure. Sintered granite cutting blades can also be used for cutting soft materials at slower speeds.

Looking for high-quality granite cutting blades? Order you’re now!

If you are looking for a granite cutting blade manufacturer to provide you with high-quality products, Tenyu Tools is going to be your preferred choice. We manufacture customized yet high-quality granite cutting blades which comply with international industry standards.

- Granite Cutting Blades Manufacture Machines

Granite Cutting Blades: The Ultimate FAQ Guide

Granite Cutting Blade Manufacturers across the globe have been stressing upon products that comply with the universal standards.

Granite Cutting Blades, often known as diamond saw blades are manufactured globally. While there is an abundant number of them available in the market, customers are hardly able to figure out which one they should buy. Tenyu Tools, China as a preferred granite cutting blade manufacturer, brings you this definitive guide to help you get answers to the questions that might be lingering in your mind.

Answers to some frequently asked questions on Granite Cutting Blades

What kind of blades are produced by granite cutting blade manufacturers?

Granite cutting blades are synonymous to Diamond saw blades. They are one and the same product with two different names. Granite cutting blade manufacturers market these blades with the name “Diamond Saw Blades”. And that is the name they are known by. We at Tenyu Tools, make sure to meet customer requirements for desired specifications such as the inch size, arbor size and more. These blades are suitable to be used for cutting a variety of materials such as granite, marble, hard stone, etc.

Do diamond saw blades and granite cutting blades have the same function?

Diamond Saw Blades is another name for Granite Cutting Blades. Therefore, they have the same application. Depending upon what percentage of cobalt, and the grade of diamonds is used, the segment size and other factors, granite cutting blades can be used to cut granite from class 1 to class 5 under different cutting situations while wrenching out the maximum performance with increased cutting efficiency and improved segment lifetime. Tenyu Tools being a preferred granite cutting blade manufacturer, lets you have a product that not just performs but outperforms.

How do granite cutting blade manufacturers produce diamond saw blades?

Granite Cutting Blades are manufactured using tempered, and high-grade steel which can be alloyed with other metals. There are a series of steps in some manufacturing processes that can be employed to come up with a finished product.

There are multiple ways in which a granite cutting blade can be manufactured. These processes can be classified into three types:

- Electroplating

- Vacuum Brazing

- Sintering

Electroplating

The process of electroplating allows granite cutting blade manufacturers to produce a thinner blade. Thickness is an important factor when you are looking to cut granite without chipping the stone. If your blade is thin, it will give you cleaner cuts without wasting excess material.

Thin blades can be helpful in achieving precision cuts.

The process of forming thin granite cutting blades is done by using electric current to fuse diamonds onto the metal surface. This affixes them onto the metal surface and provides the metal a durable and precise cutting angle.

Vacuum Brazing

The process of vacuum brazing involves welding diamonds to the surface of the granite cutting blade. This way, diamonds can be attached to the outer surface which result in a fast cutting speed i.e. ideal for cutting hard materials like granite. Since blades manufactured using vacuum brazing are not thin, they produce rough cuts and may also produce chipping. In order to get precise and clean cuts, you might prefer using electroplated blades.

Sintering

One of the most common types of granite cutting blade is the sintered blade. They are manufactured using a steel base of the blade which is covered in micro-sized diamond segments. These segments are fused to the blade using heat and pressure. This process of sintering does not melt the metal, rather just fuses the diamonds to the steel base using intense pressure. Sintered granite cutting blades can also be used for cutting soft materials at slower speeds.

One of these three processes can be employed by your preferred granite cutting blade manufacturer to produce high-quality diamond saw blades that do not break at high torque applications.

Which is the best-regarded granite cutting blade by manufacturers?

Granite cutting blades that have been vacuum brazed or electroplated, are generally regarded as the best tools for cutting granite. This is not only due to the processes they are formed out of, but also the reusability factor. This means that these tools can be re-plated or re-brazed to extend their life.

Furthermore, vacuum brazing and electroplating both have a scope beyond sintered bonds making them the best among the granite cutting blades available in the market. While electroplated blades use comparatively sharper and pointed diamond crystal grit, vacuum brazed use around but more resilient diamond crystal grit that can withstand high temperature and pressure.

How do you install a granite cutting blade?

In order to install a granite cutting blade, you will first need to take the old and worn blade out of the arbor. To do this you would need the help of an Allen Key and a spanner. Use the spanner to hold the arbor chuck in place while applying rotational force in the Allen key socket using an Allen key. Rotate the same in a clockwise direction until the arbor falls apart. Carefully remove the blade out of its place. Now, use a new blade and insert it in its designated place. Insert the outer cover and the arbor back in place. Use the spanner and the Allen key again to tighten the screw-type assembly. The circular saw is now ready to be used.

How do you avoid rust on a granite cutting blade?

Though granite cutting blade manufacturers take appropriate measures in preventing your blade from rusting, sometimes the case can be otherwise. Your granite cutting blades can catch rust if left unattended for a long time. This can result in the steel base becoming weaker, which might break during its operation. This can be hazardous as you might face injury. However, there are some steps you can take to prevent your blade from catching rust.

These include-

- Manual Derusting

- Semi-mechanical Derusting

Furthermore, there are several other techniques that are employed for mechanical and chemical derusting. They can be chosen depending upon the intensity of corrosion that you are dealing with.

Manual Derusting methods may include the use of force from a hand hammer, a shovel, sharp-edged object, a wire brush, and such objects with the motive of removing rust particles from the blade surface.

Semi-Mechanical Derusting involves the use of air-driven brush wheels and such derusting machines to get the rust off the blade surface.

Other techniques of avoiding rust include the use of Compressed-air blast also known as Centrifugal blast rust removal using oil-free compressed air, and chemical methods in which an inorganic dilute acid solution is used to brush and soak the rusty metal surface.

Alternatively, an anti-rust coat can always be used to keep the blade surface off the direct contact of rusting agents.

How many teeth does a granite cutting blade have?

The number of teeth on a blade varies as per the blade size. Handheld circular saws can accommodate smaller carbide-tipped blades which are 4-½ inches to 7-¼ inches in diameter. Tile cutting saws can accommodate 7-inch to 10-inch diameter cutting blades. Table saws and compound miter saws can use blades 10 inches to 12 inches in diameter. Whereas, circular saw blades used for metal cutting and chopping(like those of abrasive saws or cut-off saws) use aluminum oxide or silicon carbide blades that are 14-inches in diameter.

From the above information, we can easily deduce that granite cutting blades can be anywhere between 4 inches to 14 inches in diameter. Under typical conditions, smaller granite cutting blades with 4 inches- 5 inches dia have 8 to 10 teeth on the circumference, whereas those with a larger dia can have up to 40 teeth. This number may differ as the blade diameter varies.

If you want to ascertain the number of teeth on the blade that you are using, you can check the label stuck to the package in which your blade arrives.

How to choose the size and teeth for a granite cutting blade?

Selecting a granite cutting blade depends upon what thickness of the granite slab you have. Based on that you will need to select the type of granite cutting blade. Granite cutting blade manufacturers produce three types of granite cutting blades, vacuum brazed, sintered, and electroplated cutting blades.

Now, if you are abreast with the process of blade manufacturing using these three processes, you can easily deduce that sintered blades are usually thick in comparison to electroplated and vacuum brazed ones.

Therefore, if you are looking to cut granite that is thick about more than 1-½ inches to 2 inches, you would need a sintered granite blade. Also if you are not expecting a very clean finish and cut, sintered blades are definitely the ones to go for.

On the other hand, if you are looking for cleaner cuts and less chipping, you would need to set your eyes upon electroplated or vacuum brazed granite cutting blades. These blades are comparatively thin and can produce precise and cleaner cuts at a lesser chip-off rate.

How do you sharpen a granite cutting blade?

Unlike blades used for cutting through wood, granite cutting blades have a different cutting action. Granite cutting blades have grits/ small segments of the diamond that grind through the granite surface at high speeds. These diamond grits are tough and have the tendency to wear down a hard surface like that of granite, marble, and more.

Where sharpening other blades would be like using a grinding wheel and giving an edge to a steel blade, sharpening a granite cutting blade is entirely different. It involves making a slurry of abrasive material and covering the blade periphery with the same.

Another way to do so is by making the blade cut through a block of abrasive material made especially for blade dressing purposes and sharpening it.

There are a series of steps you can follow if you are looking to sharpen your granite cutting blade:

You’ll need a dressing block for your blade to cut through the same. Make sure you have an adequate amount of coolant going through the process so there is less heating and the blade doesn’t wear out.

- Switch on the circular saw and cut through the abrasive block four to five times.

- Turn it off and allow it to stop.

- When it has come to rest completely, you will need to examine the entire edge of the tile saw blade.

If the blade has sharpened, you’ll feel roughness on the edge. If it’s all dullness across the edge, you will need to repeat the process again.

Repeat the entire process until the outer edge of the cutting blade is dressed completely.

What causes a granite cutting blade to shake?

There can be more than one reason for the granite cutting blade to shake. Some of them include:

- The blade rotates at an improper speed.

- The size of the arbor hole on the blade does not match that of the saw shaft.

- The blade geometry has been disturbed.

- The blade has lost its tension.

Ways you can troubleshoot these issues are discussed below:

The blade rotates at an improper speed

Improper speed issue arises when there is some issue with the motor speed, or with the shaft on which it moves. In such a case, you can check for worn out bearings, mounting arbor or a bent shaft which can be a result of mishandling your circular saw blade. The speed of the saw should be verified according to the respective industrial standards stipulated in your region.

The size of the Arbor hole does not match with the saw blade

In such a case, you can check for the blade collar discs to ascertain they are clean and of correct diameter. If the diameter differs, you may need to change your blade and choose the one with the same arbor hole size as that of the circular saw arbor.

Blade geometry has been disturbed

There can be a chance that the granite cutting blade is twisted due to dropping or mishandling at the end of the manufacturer or the supplier. You can simply get the blade replaced by the granite cutting blade manufacturer or supplier you had purchased it from.

The blade has lost its tension

This reason for the blade to shake can be due to several factors. The steel core that the blade is mounted on may be overheating while it is being used. In such a case you can consider tightening the blade shaft nut and make sure the drive pin is functional while cutting. Also, make sure adequate coolant supply is being facilitated.

Another reason for the blade to lose its tension is the workpiece instability. To avoid that make sure the workpiece is held intact and does not move during cutting.

If you have followed all the steps, and the blade still shakes, the best is to get the blade replaced by your granite cutting blade manufacturer or supplier.

Tenyu Tools as your preferred granite cutting blade supplier makes sure you get quality blades that are in their best shape.

Are more teeth on a granite cutting blade better?

Considering the type of task you have to accomplish, the number of teeth on your granite cutting blade will depend upon the size of the blade you are using. Granite cutting blades can be anywhere between 4 inches to 14 inches in diameter. Under typical conditions, smaller granite cutting blades with 4 inches- 5 inches dia have 8 to 10 teeth on the circumference, whereas those with a larger dia can have up to 40 teeth. This number may differ as the blade diameter varies.

Therefore, more teeth will mean that you get a cleaner cut whereas, a lesser number of teeth indicates that you get a rougher cut. So the blade is only as good as the task it is to be used for. You need a cleaner cut, go with more teeth, you need a rough cut, have the one with the otherwise.

How to get better cuts from granite cutting blades?

If you are looking to obtain better cuts using your granite cutting blade, you’ll need to follow a strict process. The process involves having a work area like a workbench that is stable enough to counter vibrations and such forces. You can make the workpiece stable by using C-clamps to hold them in place. Make appropriate markings by measuring the dimensions using a measuring tape. You can also use masking tape to mark the area you will be making a cut on. You can draw a line on the masking tape after you have applied it. This line will serve as a visual aid while you are cutting the workpiece.

Use the appropriate granite cutting blade according to the purpose. No matter what type of saw you are using, you will need a high-quality granite cutting blade which is easily available at Tenyu Tools.

While you are cutting granite, be sure not to force the saw into the granite, as this will only damage the blade by disturbing its normal motion. Also, the cut so obtained will not be as per your expectations. Use both your hands to do the job as this will ensure you have a stable workpiece as well as a stable and uniform cutting saw.

Make sure to provide adequate coolant supply as it prevents the granite cutting blade from getting overheated. If the blade gets overheated, the geometry may get disturbed and you’ll need to change the blade from over your granite cutting blade manufacturer or supplier. This will only result in additional costs which you certainly won’t like.

Do granite cutting blade manufacturers allow for customization of blade properties?

Yes, the diamond grit size can easily be customized as per individual requirements. Also, if you want a thicker blade for heavy granite slab cutting, you can communicate the same over to your granite cutting blade manufacturer or supplier and they may produce the same for you.

If you have been looking for customized granite cutting blade requirements, Tenyu Tools is the best manufacturer for you to reach out to.

Contact us for more queries!

If you have any additional queries on granite cutting blades, please feel free to reach out to our helpline numbers at any time of the day.