Custom Saw Blades

- Tenyu: Your Leading Custom Saw Blades Manufacturer & Supplier

- You can trust us as we’ve been in business for over 15 years!

- Your custom saw blades will exactly be how you need them to be!

- You can experience high-quality customer service!

- You can choose from the wide catalog of saw blades we offer!

Your Trusted and Reliable Custom Saw Blades Manufacturer Tenyu Tools Offer Industrial Quality Products

Why Choose Tenyu Tools Co., Ltd.?

Why should you choose us for the custom saw blades you require?

Tenyu Tools is China’s leading custom saw blade manufacturer for over 2 decades!

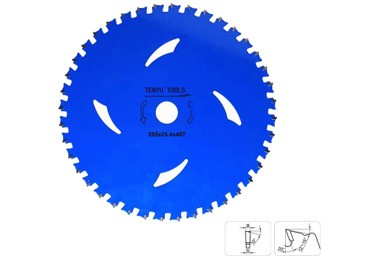

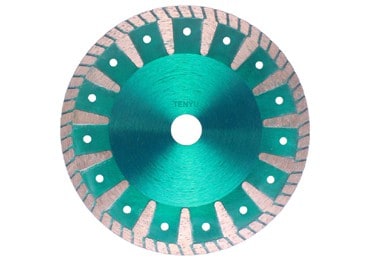

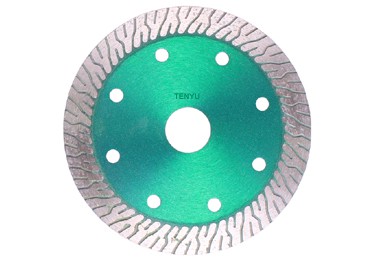

You can get whatever cutting tool or accessory you need from us! Whether you need wood cutting blades, diamond cutting blades, grass cutting blades, and so on!

If you need customized saw blades, Tenyu Tools Co., Ltd. will absolutely deliver!

Tenyu Tools’ Custom Saw Blades

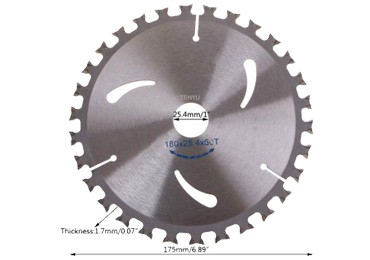

If you need custom saw blades, our company can get you exactly what you need! Tenyu Tools can manufacture a wide range of pre-made and custom saw blades.

Whether you need regular wood saw cutting blades, aluminum cutting blades, diamond saw blades, you can trust us!

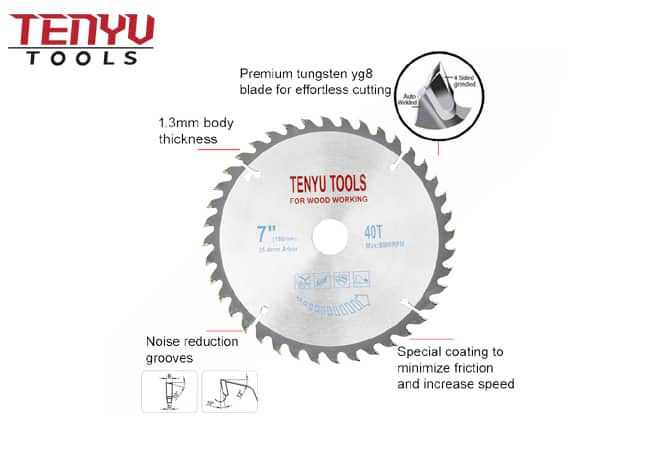

Tenyu Tools’ circular saw blades are high frequency, stable, and made of high quality steel!

- Features and Benefits

- Applications

- Other

Your custom saw blades could be met by the precision and accuracy of Tenyu Tools’ Research & Development (R&D) team.

So, whether you need a pre-made saw blade or a custom saw blade, you’ll never go wrong in choosing us! All our custom saw blades are:

- Produced using Tenyu Tools-manufactured machines

- Made out of high-quality steel

- Noise reduction

- Heat dissipation

- Can be used for both wet and dry cutting

Those are some of the features our custom saw blades have.

Applications of Tenyu Tools’ Saw Blades

You can get a hold of our custom saw blades no matter what industry you’re in.

Tenyu Tools provide different kinds of high quality Custom Saw Blades

Whether you’re in the structural industry, agricultural industry, woodworking industry, even in the steel industry, custom made Tenyu Tools circular saw blades will be the best option you can have!

Even if you’re not a business – if you’re a reseller or a distributor, you can also take advantage of our custom saw blades!

Capabilities Of Our Saw Blades

The best part about choosing us here at Tenyu Tools is that you can have customize your order!

If you require a certain amount of teeth; if you need a specific tip, and the like, we can do it for you!

Tenyu Tools can produce hundreds of custom saw blades on a daily basis! We can give you the assurance that we’ll meet what you require in just a short period of time!

Other Products We Offer

Apart from custom saw blades, Tenyu Tools can also be your top source of other products, including:

- Grinding Wheels

- Drill Bits

- Hole Saws

- Nibble Cutters

- Screw Extractors

- And Many More!

Don’t hesitate to contact us if you can’t find a manufacturer you can trust when it comes to custom saw blades.

Send us here at Tenyu Tools Co., Ltd. an email about the products and orders that you need!

Custom Saw Blades – The Comprehensive FAQ Guide

Many businesses need custom saw blades for their business/operations. Out in the market, there are a lot of types of these saw blades you can choose from.

And in the event that you’re not sure of what these saw blades are, this guide is perfect for you!

Today, we’ll unravel everything you need to know about custom saw blades. What they are, what they can be functional for – and everything else!

What are Saw Blades?

They’re rotating cutting tools that come in the shape of circular blades with edges (teeth).

Their main use is to cut certain materials, with wood being the most common. Apart from wood, though, you can also cut concrete, diamonds, steel, and so on.

Can You Customize Saw Blades?

Yes, there are manufacturers that offer customization of saw blades as well as other products.

Many manufacturers offer custom made saw blades, drill bits, and other cutting tools. You can customize the teeth, the dimensions, the edge sharpness, and so on!

What are Ultra Thin Saw Blades?

From the term alone, ultra thin saw blades are saw blades you can use for cutting thin, delicate materials.

What they are for is to have very little waste, with the cuts being accurate and being precise. You would want to use them for cutting thin pieces, not thick and tough hardwoods.

Top Cutting Blade Manufacturers

On a global scale, there are a lot of saw and cutting blade manufacturers you can trust.

What tops the list, however, are:

- Diamond Saw Works, Inc.

- PILANA

- Dimar

- Lennart GMBH & CO. KG

From where you are, there could be other manufacturers. But if we were to summarize the best in the globe, these are the top companies.

Different Types of Saw Blades

You can categorize saw blades in many different things. But, the best and the most acceptable would be the distinction between their teeth, shape, and grind.

Alternate Top Bevel (ATB) (Beveled)

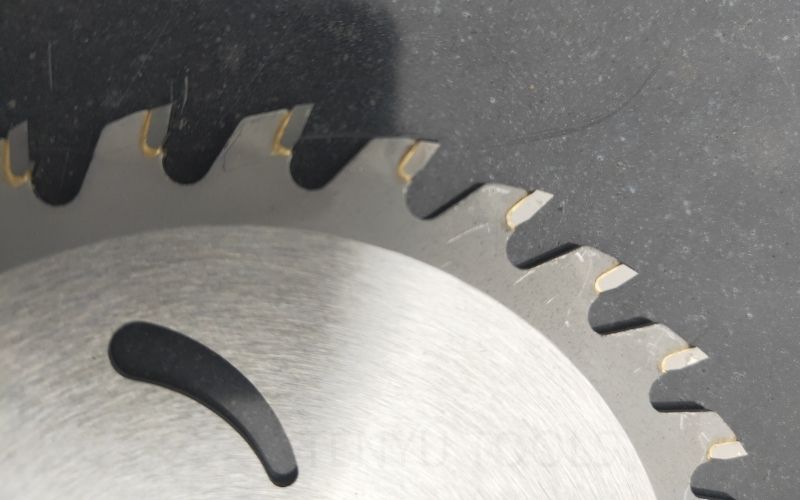

With ATB blades, the teeth have an angle across its top edges.

Each tooth lean in on the opposite direction, and the shape causes it to shear using a slicing motion. The steeper the bevel, the cleaner the cuts would be.

Flat Top Grind (FTG)

An FTG blade would have teeth where the top edges are square.

The effect of this would be more of a chisel chop. It’s fast, but it’s not as clean as ATB blades with steep bevel angles.

Triple-Chip Grind (TCG) or Trapezoidal

In a TCG blade, the teeth are alternating between a chamfered and a raker tooth.

The former is the agent that roughs the cut out, the raker tooth is what smoothens and cleans it out.

Combination (ATBR)

Lastly, combination or ATBR blades are completed with 50 teeth. All of which are arranged in sets of five (5) each.

It’s comprised of four (4) ATB teeth and a raker tooth. The main purpose of ATBR blades is to saw and cut dense and thick materials.

Saw Blade Teeth Guide

As we all know, the teeth on saw blades are all different. Teeth structure is important as it will determine the type, quality, and the size of the cut.

For you to have a clearer and a better understanding of it, you can think of it like this:

Blades with higher teeth amount can produce cleaner work, faster. Blades with fewer teeth count, however, can produce rough cuts and have aggressive action.

When it comes to the shape of the teeth, the ATB is ideal for cross-cutting veneered plywood and solid woods.

TCG blades are for harder and tougher materials; it can deliver clean cuts on non-ferrous or laminated objects and materials.

How Do Saw Blade Teeth Fall Out?

Whether you have custom saw blades or pre-made saw blades, teeth on it can fall out.

The most common reasons for the falling out or breaking of saw blade teeth include:

- Higher feed rate

- Wrong pitch of tooth

- Higher feed pressure

- Damage to the handling

- Incorrect blade butt-weld

- Improper positioning or clamping of material

- Unnecessary movement during cutting

- Teeth hits certain parts of a machine

- And many more

It’s not uncommon for the teeth of saw blades to fall out or get broken.

That’s why you need to avoid these things to prevent it from happening.

Which Saw Blade Makes the Smoothest Cut?

Generally, saw blades that have more teeth make smoother cuts, but at a slower rate.

Apart from that, the number or the count of teeth on a blade also helps determine the speed and the type of finish.

What are Cold Saw Blades?

They are circular saw blades made to cut metal, while also keeping the material cold; because by friction, it is supposed to get hot.

How is this done? It’s done through the generation of heat to the cut chips and bits. The blade, as well as the material remains cool.

How Do You Remove Burrs?

A burr is the deformation of the metal at the edge of the saw blade.

You can find it to be a small fold on the metal; typically on the edge of where the grinding occurs.

There are a lot of ways on how to remove a burr. Some of the most common ones include:

- Micro-burr removal

- Water-stone burr removal

What Can You Cut With Custom Saw Blades?

Custom saw blades are among the most powerful and the most accurate tools for cutting.

Since it’s customized or “custom made,” you can specify it to cut a specific or a particular material.

- Wood

- Hardwood flooring

- Metal

- Plastic

- Bricks

- Concrete

- Diamonds

Its use will really depend on the material, the shape, the amount of teeth, and the size.

How are Saw Blades Deformed?

Saw blades can be deformed in a lot of different ways. However, the most common reasons why they deform or warp, include:

- The blade guide is already out of alignment

- Improper riding of the worn guides on the blade

- Adjustment of guides are too tight or close

- Exceeding temperatures of the blade capability

These are among the most common reasons why some saw blades are deformed.

There are others, but those would already depend on the custom saw blade cutters that you have.

What are Saw Blade Burns and How Can it be Prevented?

Saw blade burns are marks on the edges of wood, or other materials after it’s cut. It’s labeled as “burns” as it’s the result of too much heat produced by the saw blade.

Source: Cutting Edge Saws

There are a couple of things you can do to prevent this from happening. Some of which include:

- Sharpening the saw blade (dull saw blade would take more time to cut, producing more friction)

- Cleaning the saw blade (dirty materials can make it duller and weaker)

- Set the feed rate faster, if applicable (slower feed rates tend to cut slower)

- And others

Wood Cutting Blades vs. Diamond Saw Blades

Can a diamond cutter cut wood too? Most people will answer yes, since diamond is harder than wood.

While that’s true, it might not be effective and efficient altogether.

Diamond saw cutters can be used for a lot of hard materials like concrete, steel, tile, etc.

However, its harsh grit can create rough cuts, which can rip the fibers apart, creating misaligned and crooked cuts.

There are specifically-made wood saw cutting blades that are purposely created for wood.

Their coatings will primarily be made especially for the purpose of cutting wood, not any other material.

What is the Thickness of a Standard Saw Blade?

As there are custom saw blades, there’s a regular or a standard size or specification of it.

The usual or the standard size of a saw blade is at 1/8 to ¼ inches.

What are Carbide Tip Custom Made Saw Blades?

It’s a type of a saw blade where the main body of it is made up of steel.

But, its tip or edges are brazed to the body of the tips. This can have a lot of advantages, including edge-holding up to ten (10) or twenty (20) times longer than regular steel tips.

What are Advantages for the Cutter Head for Fully Automatic Welding Machines?

Akin to welding, automating the cutting procedure can give you a lot of benefits.

Some of the main advantages or benefits for automatic welding machine cutters include:

Improved Quality

Automating the cutting procedure for fully automatic welding machines can increase the quality or the result of the process.

Reduced Labor Costs

With machines and automation, there’ll be less or reduced labor, which results to reduced or decreased costs in labor.

Reduced Scrap or Waste

Since you’ll be programming everything from start to finish, it will be controlled.

The speed, the direction, etc., resulting to a significant decrease in waste or scrap.

Increased Output

Last but definitely not the least would be the increase in the output.

Since there’ll be less people or workers, and everything will be machines, you can designate people to work on other things that can complement the procedure.

These are just some of the benefits that a cutter can have with a fully automated welding machine.

Coated vs. Uncoated Saw Blades?

There have been a lot of misconceptions between coated and uncoated saw blades. But what’s the difference?

Let’s start by discussing each of them.

Coated Saw Blades

Most coated saw blades are made from HSS or high-speed steel. It’s a type of steel, typically softer than high carbon steel, but is still a strong alloy.

Some of the advantages you can get from using coated saw blades include:

- Harder and tougher tooth edge

- Lesser or decreased friction and resistance

- Can make the blade sicker

- Longer-lasting

Uncoated Saw Blades

While coated saw blades seem like the type that you really need, you might be surprised with what uncoated blades can offer.

Also commonly referred to as “naked blades,” they’re blades without any protection.

Akin to coated saw blades, they can be HSS – even stronger steel.

Some of the advantages you can get from uncoated custom saw blades include:

- Can be sharpened over and over again

- It’s cheaper and less expensive than coated saw blades

- Does not need any coating to be sharp

What Quality of the Saw Blade can be Improved by Full Automation of Gear Grinding?

The best saw blade quality that could be improved and enhanced through gear grinding automation would be life expectancy, as well as efficiency.

By integrating automation, the products/outputs would have better and higher quality.

In addition, the life of the saw blade would be longer since everything will be controlled.

Uses of Carbide Tip Saw Blades?

Carbide tips are complementary tools that help custom saw blades in the cutting process.

Its main function is to improve and enhance the cutting to make it smoother, cleaner, and better.

Tips in Finding the Best Manufacturers of Custom Made Saw Blades

Out of all the many custom made saw blade manufacturers in the market, it’s going to be hard to choose.

But, you can consider the following factors to see if a certain manufacturer is what you need.

- Experience & Knowledge

- Qualities and Certifications

- Reliability, Transparency, and Skillset

Where Can You Find the Most Reliable Custom Saw Blades Manufacturer?

China is one of the many countries housed by a wide range of talented businesses.

We here at Tenyu Tools Co. Ltd. is considered as the best in producing custom saw blades, drill bits, and other tools.

You can trust us to customize and to create the specific type of saw blades you need for your project.

Why Choose Us?

Tenyu Tools Co., Ltd. has been topping the charts since the early 2000’s. For over 2 decades, we’ve done nothing but give our clients high quality custom made saw blades!

- You can trust our R&D team to get you the specific saw blades that you need

- You’ll never worry about the quality – we have a quality assurance (QA) team

- We have our own machining service, creating and innovating the machines that we use to make our tools

- We offer our products to over 20 countries from all around the globe

Don’t hesitate to give us a call here at Tenyu Tools for the custom saw blades that you need!

Wherever you are, you’ll be able to get your orders in a 2-3 week timeframe!